How To Replace PFAS

Hardly any other chemical substance can compete with PFAS, due to their unique properties. That explains why it is so hard to find a replacement for these toxic “forever chemicals”, which accumulate in the environment and do not break down over time. A team at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM has succeeded in developing solutions that hold great promise of targeted substitution for PFAS in fields including medical engineering.

The planned ban on the use of per- and polyfluoroalkyl substances (PFAS) in the European Union is having a drastic effect on health technology. These substances have many properties essential for use in medicine, so they are currently used in many standard products. In light of the time it takes to launch a product on the market — generally well beyond the transitional periods that have been proposed to date — the medical technology industry needs to act quickly to find alternatives that can be implemented quickly and meet the sector’s stringent safety standards.

Harnessing proven methods for medical applications

Researchers at the Fraunhofer IFAM have set themselves the task to support companies in these efforts. Dr. Ralph Wilken, Head of the Surface Technology division at the institute, is an expert on PFAS. Long before the toxic substances started attracting negative attention, he knew he wanted to find alternatives. The results have been impressive: “We have now been using organosilicon chemistry for more than two decades to find effective substitutes for a broad spectrum of positive properties of PFAS,” Wilken notes.

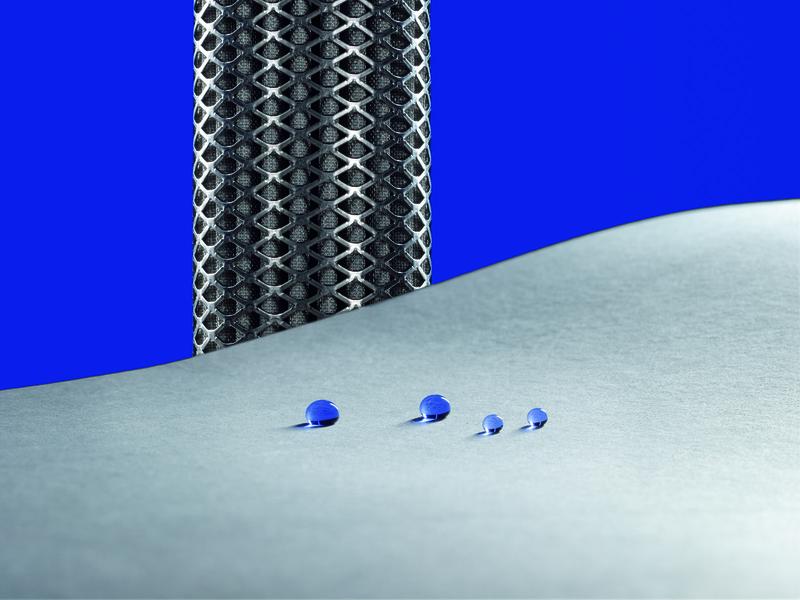

The solutions that Wilken and his colleagues have developed are being introduced right now in sectors such as the food industry, and they meet the standards required for use in medical technology: They are biocompatible and therefore both tolerated by the body and inert, i.e., they do not or barely react with other substances. The experts have also succeeded in developing numerous coatings that feature electrically insulating properties and can be optimally adjusted in how they interact with cells via their surfaces.

Custom-fit solutions

Whether in products themselves or used in production, one key point when it comes to replacing PFAS with no loss of functionality is making sure the solution is customized for the specific use case: “We can analyze the component that needs to be replaced in detail, thereby zeroing in on a substitute that exactly matches the desired properties. At the same time, we can provide our partners with in-depth support in the form of proven processes, our knowledge of surfaces and functional materials, and our experience with which materials can be replaced effectively and how. It doesn’t take long to get to a result that customers can work with,” explains Dr. Kai Borcherding, Head of the Medical Technology and Life Sciences business unit at Fraunhofer IFAM.

The experts are scheduled to attend the COMPAMED 2024 trade show from November 11 to 14 to present their solutions at the joint Fraunhofer booth at Booth G10, Hall 8a. The solutions on display will include innovative coatings, the ReleasePLAS® plasma polymer functional release coating, which enables release agent-free production of plastic components, the PLASLON® non-stick coating, and solutions for functionalization of surfaces such as silicone modified by vacuum ultraviolet (VUV) radiation.

ReleasePLAS®: Register number DE 30 2013 037 673

PLASLON®: Register number EM 019027070

Weitere Informationen:

https://www.fraunhofer.de/en/press/research-news/2024/november-2024/how-to-replace-pfas.html

Die semantisch ähnlichsten Pressemitteilungen im idw