Microstructured Reactor Nitroglycerine Plant - Test Runs Successfully Finished

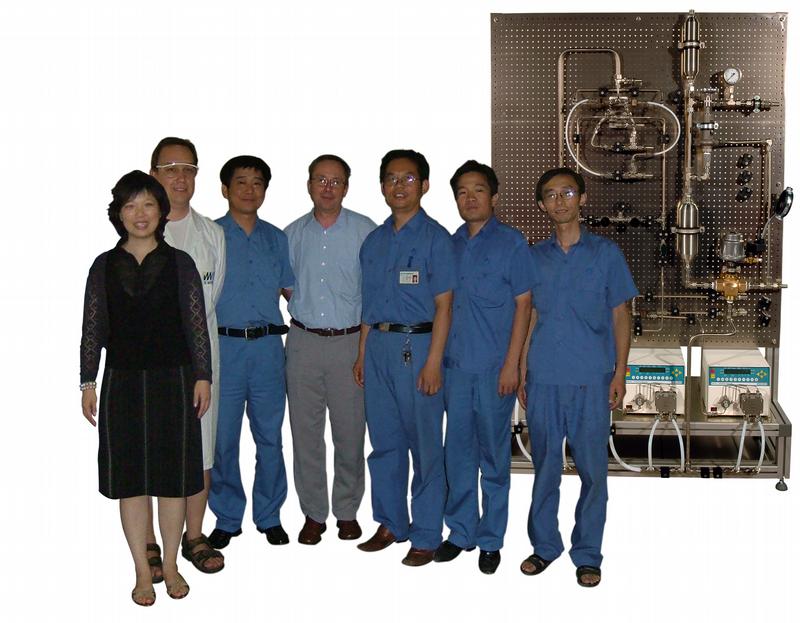

On September 27th, 2005, six months after signing a co-operation agreement, the test runs of a microstructured reactor plant for nitroglycerine production have been successfully completed at Xi'an Chemical Industrial Group (HAC) in China. Under supervision of Prof. Dr. Holger Loewe, Director R&D of the Institut fuer Mikrotechnik Mainz GmbH (IMM), Germany, a team of engineers and chemists around Dr. Bernd Werner designed and constructed a continuous flow nitroglycerine plant. The plant was established on-site in the framework of a long term co-operation agreement to explore possible applications for the production of fine chemicals, specialties and commodities with microreaction technology.

This new erected plant allows to produce nitroglycerine continuously with a throughput of approximately 15 kg per hour. The manufactured nitroglycerine will exclusively be used as a drug for acute cardiac infarction. Therefore, the product must be made under GMP conditions and the quality of the product has to fulfill highest standards. The microstructured reactor plant consists essentially of three main parts: the mixing of sulfuric acid with nitric acid, both highly concentrated fuming liquids, the reactor and the phase separation, washing and purification devices. On demand, glycerine and the acid mixture are fed separately into a microstructured reactor where mixing occurs within milliseconds. The high surface to volume ratio of these new type of reactors ensures an immediate transfer of heat released by the reaction. An increased safety compared to conventional processing is achieved by the small volume hold-up in the microstructured reactor. In summary, higher yields, better product quality, increased safety and a reduction of environmental hazards are the main advantages by applying microstructured reactors not only for this type of chemical reactions.

Having the test runs of the nitroglycerine plant completed successfully after final inspection and acceptance by HAC it was decided to extend co-operation with IMM in terms of investigating reactions suitable for processing in microstructured reactors.

Weitere Informationen:

http://www.imm-mainz.de

Die semantisch ähnlichsten Pressemitteilungen im idw