Power Plants that Purr - Quiet Industrial Facilities

How can the noise generated by power plants and substations be minimized? A team from Siemens Power and Gas' Acoustics Department specializes in simulating and optimizing noise and vibration reductions.

Few people would be irritated by the sound of leaves rustling in a gentle breeze. However, if a power plant were to produce the same level of sound in its surrounding environment — about 35 decibels — people would respond very differently. With this in mind, a dedicated team of acousticians at Siemens’ Power and Gas division is using advanced simulation to reduce power plant ambient noise to the lowest possible levels.

Simulation technology makes it possible to minimize noise output by modifying and testing a power plant’s noise sources before the plant is actually built. Construction begins only when everything has been optimized. Established in 1987, the acoustics team has significantly reduced the noise output of a number of power plants.

Sound Clouds

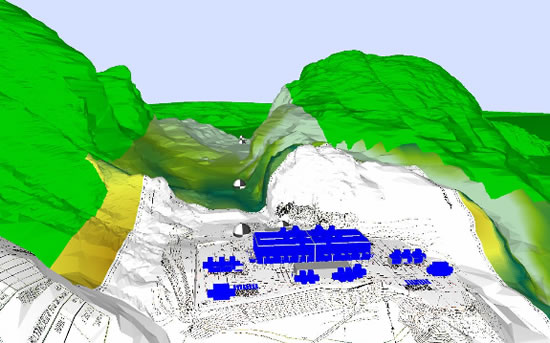

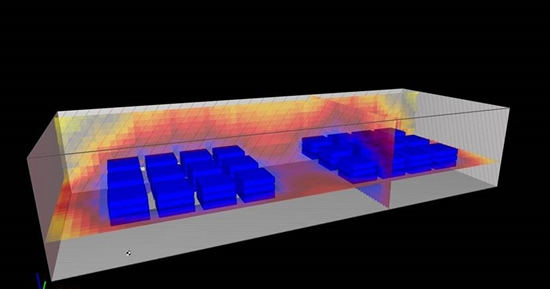

Based in Erlangen, Germany, the acoustics team not only optimizes the sound levels of power plants but also of electrical substations. Working with three-dimensional models that can represent a facility as large as four soccer fields, they look carefully at every detail. Noise appears as colored cloudlike shapes. The team first looks at the distribution of noise inside structures such as substation halls, keeping every conceivable parameter in mind. In addition, in order to achieve a deeper level of acoustic simulation, the team needs know things such as where the substation will be located, the kinds of building materials that will be used for its construction, and the shape and size of the building. In the next step, the noise level inside the hall is determined with the help of acoustics software and data from comparative measurements. These are the data that the acoustics experts need for their simulation and their noise control measures.

Keeping Noise Inside

After the acoustics team has calculated how high the noise level inside a structure will be, they simulate sound propagation outside.“A tree there, a bush here, a path, a house, a street, a bridge — in a simulation, every detail of a facility’s future surroundings is reproduced,” says Holger Ennes to describe the 3D image on his display. “We also take into account variables such as an area’s wind features, air absorption, soil absorption, temperatures, and obstacles to sound transmission.”

The resulting sound propagation data is then compared with statutory noise protection limits and the customer’s requirements. If the calculated value exceeds these limits, or if the noise level can be further minimized, Ennes and the team recommend changes to the layout of the facility that would further reduce noise levels. Sometimes these changes involve thicker facades or noise barriers; other situations may require outdoor components to be enclosed, for example with soundproof hoods for transformers or pumps.

As Ennes enthusiastically explains, “Our acoustics team works on noise protection for power plants and electrical substations on land, but also on substations in the North Sea. That’s because when an offshore wind farm is being built, steel piles have to be driven into the sea floor. The noise that is generated at such sites is transmitted four times faster through water than through air, and it is not allowed to exceed a certain limit.” Any excessive noise could cause damage to marine mammals. Here too, noise-reduction measures must be implemented by specialists.

Contact:

Sebastian Webel

Editorial Office

Siemens AG

sebastian.webel@siemens.com

Original Internet Article:

https://www.siemens.com/innovation/en/home/pictures-of-the-future/digitalization-and-software/simulation-and-virtual-reality-power-plants-that-purr.html

Pictures of the Future

https://www.siemens.com/innovation/en/home/pictures-of-the-future.html

Ähnliche Pressemitteilungen im idw