AutoPanelSizer 4.0 now generates better cutting plans in less time

Fraunhofer SCAI has greatly improved its successfully marketed AutoPanelSizer software. The new version now optimizes plans for cutting rectangular parts much faster. New features and the utilization of multiple processor cores ensure even more efficient cutting plans. As a pure optimization kernel, the software can be integrated into existing plant control systems or ERP/MES systems.

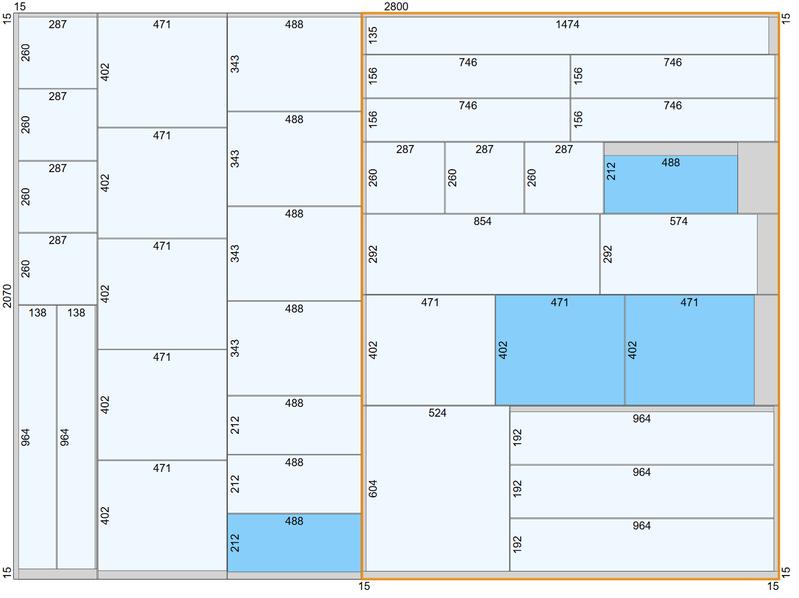

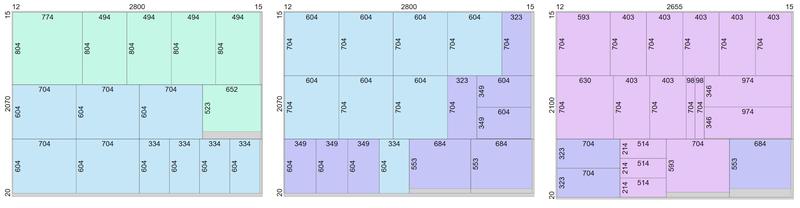

SANKT AUGUSTIN. Cutting panels into smaller rectangular parts belongs to the daily routine in many factories. In the woodworking industry and in industries requiring metal or glass cutting, a lot of waste is generated in the process. With its AutoPanelSizer software, the Fraunhofer Institute for Algorithms and Scientific Computing SCAI delivers a cutting optimization that minimizes this waste while taking production times and costs into account. SCAI is continuously improving the powerful optimization algorithms and adding new features. The new version 4.0 works significantly faster than its predecessor and optionally runs in parallel on multiple processor cores. In addition, the new version can integrate stress release cuts into the cutting pattern to reduce tensions in the panel material prior to actual cutting.

AutoPanelSizer is a pure optimization kernel without a graphical user interface. The program is primarily aimed at software providers or saw manufacturers, who can integrate the cutting optimization into their existing software solution in order to offer their customers added value and a competitive advantage. AutoPanelSizer can also complement existing optimization programs to increase the quality and diversity of solutions. AutoPanelSizer is already in use by end customers as an optimization module of various ERP and MES systems. It is also part of the cloud solution of a major machine manufacturer.

The cutting plans generated with AutoPanelSizer already achieve a very high material yield with only two cutting stages. Recuts and head cuts, a third cutting stage, and the consideration of optional parts reduce waste even further. AutoPanelSizer can be adapted to specific application scenarios through various individually adjustable machine properties. Predefined production sequences or a limited number of destacking stations are also taken into consideration by the software. In addition, the optimization algorithms take into account not only material consumption but also manufacturing costs and production times – allowing users to balance optimum material utilization against production effort.

At SCAI, individual customer requirements are incorporated promptly into the development of the software. The development team can draw on many years of experience and a broad algorithmic knowledge in the field of optimization: Fraunhofer SCAI has been providing solutions for packaging and cutting problems in various application fields for more than 20 years. In addition to AutoPanelSizer, the software suites from SCAI include the programs AutoNester and PackAssistant. AutoNester is one of the leading cutting optimization solutions worldwide in the textile and leather sector and is used for nesting complex parts. PackAssistant is the world's leading software in the field of optimizing packing arrangements of identical parts into containers.

Distributors can request a free demo version of AutoPanelSizer to see the quality of the cutting plans and compare them with existing solutions. End users can contact partners of the institute or initiate an integration of AutoPanelSizer through their own software or machine partner.

Weitere Informationen:

https://www.scai.fraunhofer.de/en/business-research-areas/optimization/products.html

Ähnliche Pressemitteilungen im idw