Secondary raw materials to save resources and CO2: IN4climate.NRW develops solutions for a circular economy

The circular economy – or closed-loop recycling of raw materials – can contribute significantly to defossilisation and achieving the goals of the Paris Climate Agree-ment. It also saves valuable resources. The IN4climate.NRW federal state initiative provides an overview of the current status and presents a vision of the circular economy in energy-intensive industries in its current discussion paper “Circular Economy in the Basic Materials Industry: Opportunities and Requirements for a Successful Transformation”.

Based on this paper, it has derived specific proposals for measures as well as regulatory and political recommendations for action to further close material cycles. It thus focuses on the increased use of secondary rather than primary raw materials. The content of the paper is supported by 21 partners from companies and associations in energy-intensive sectors as well as renowned research institutions.

“On a global scale, a linear economy still prevails in most sectors,” explains Dr Henning Wilts, Head of the Circular Economy Department at the Wuppertal Institute for Climate, Environment, Energy and co-author of the discussion paper. “The circular economy offers several advantages as an alternative: It has the potential to be lower in emissions and thus more climate-friendly. It also reduces resource consumption, thus reducing dependency on raw materials from abroad and combating rising raw material prices.”

Expanding industrial symbioses and adapting them to the energy transition

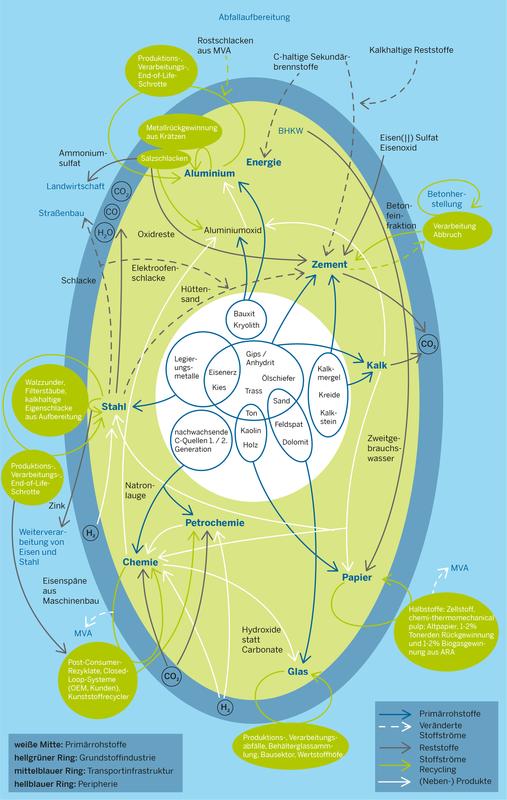

It is true that secondary raw materials – residues and by-products from basic materials industries and recycled waste – are already used as raw materials in the industrial sector today. The material flows of many industrial sectors are closely interlinked at the local level, especially in industrial federal states like North Rhine-Westphalia. Nevertheless, their potential for utilisation could be exploited much more effectively in many sectors so as to close the material cycle. This requires industrial symbioses, or cross-sector and cross-industry cooperation, along the entire value chain.

“Where circular economy models are already established, the basic materials sector faces the challenge of adapting to new production processes,” explains Dr Iris Rieth, project manager at IN4climate.NRW and co-author of the current paper. “Because the material flows between the sectors will change in the course of the industrial transformation towards climate neutrality.” One example of this is how the steel and cement industries have dovetailed. Up until now, the cement industry has used blast furnace slag from steel production as a secondary raw material. During the transformation, this by-product will be eliminated so that alternative main components of similar quality will have to be developed for the cement industry.

Specific recommendations and demands for industry and politics

The current discussion paper by IN4climate.NRW provides an overview of the current material flows in or between various basic materials industries including the chemical and petrochemical, steel, aluminium, energy, paper, glass, cement and lime sectors. The authors see potential to close material cycles both in the techno-logical development of material separation and recycling and in expanding the use of by-products and residual materials. They believe that the biggest obstacles are on the political and regulatory front. This is because the circular economy is not yet sufficiently politically anchored as a means of securing raw materials and protecting the climate. For example, it must be given greater weight in support programmes for energy-intensive industries. Therefore, the authors also formulate political recommendations for action in their discussion paper. “In order to establish a circular economy, politics and administration need to be restructured to combine waste and environmental management, economic concepts and securing raw materials in a holistic solution. After short-term incentive systems, we need the framework conditions for a self-sustaining market,” says Samir Khayat, head of the IN4climate.NRW initiative, summarising the prerequisites for achieving a functioning circular economy.

Originalpublikation:

https://www.in4climate.nrw/fileadmin/Downloads/Ergebnisse/IN4climate.NRW/AG-Papiere/2020/discussion-paper-in4climatenrw-circular-economy-raw-materials-use.pdf

Weitere Informationen:

https://www.in4climate.nrw/en/newsroom/news/news-detail/using-secondary-raw-materials-to-effectively-save-resources-and-reduce-co2-emissions/

Ähnliche Pressemitteilungen im idw