New FFP protective masks from Germany

A research project at Landshut University of Applied Sciences wants to improve the manufacturing process for protective face masks in Germany and the filter effect of the masks.

Face masks have been part of our daily lives since the beginning of the COVID-19 pandemic: as a result, the demand for FFP2 masks has increased considerably. The main beneficiaries of this demand have been manufacturers in the Far East who have a monopoly on mask production on the world market, and who tend to win public tenders due to their low labour costs. This is where a new project at Landshut University of Applied Sciences and the Landshut company ringbach GmbH is stepping in. The team wants to develop an innovative facility for the production of high-quality FFP2 and FFP3 masks in Germany. Such a facility will enable local manufacturers to produce masks on a more economical and independent basis. At the same time, the researchers are working on a non-woven material they have made themselves that has an even better filtering effect. The project is scheduled to run from July 2022 to June 2024, and has received just under 400,000 euros in funding from the German Federal Ministry for Economic Affairs and Climate Action as part of the Central Innovation Programme for small and medium-sized enterprises (ZIM).

Innovative facility concept

“Recent years have shown us how dependent Germany is on manufacturers in the Far East – in terms of both products and raw materials,” explains Prof. Dr. Walter Fischer, who is providing scientific support to the project at Landshut University of Applied Sciences. The new production concept is set to change this. This is because the special attribute of the new production facility is the on-site production of a non-woven filter material which is processed directly into the face masks and packaged without interruption – on a single production line. A patent has already been awarded to ringbach GmbH for this production process.

Whereas up to now, manufacturers have been required to purchase, store and cut the non-woven material from large-scale producers before processing it further, the planned facility will eliminate the complex logistics, the dependence on manufacturers of non-woven materials and the complex processing steps. It is also intended for the production process to be monitored with the use of visual checks on the basis of machine learning.

Better filter effect

The project team is also planning to monitor the material itself. “The non-woven filter material is generally made in what is known as a melt-blown process,” explains Fischer. “In this process, the synthetic material polypropylene is melted before being pressed through hundreds of tiny air-circulated holes. This creates wafer-thin fibres which swirl in the air flow and form an exceptionally fine fibrous web. During the cooling, the filaments, i.e. the textile fibres, finally join together and solidify into the non-woven material.” The researchers’ goal is now to reduce the diameter of the filaments. After all, the more finely these filaments are manufactured, the better the filter effect. This also improves the wear comfort and makes it easier for the person wearing the mask to breathe.

While ringbach is responsible for the industrial implementation of the facility in the project, Landshut University of Applied Sciences is providing support with its expertise in plastics technology. “We are interested in developing compounds, i.e. new composites which gain specific attributes through the addition of additives, and which can therefore be processed better in the melt-blown process,” explains Fischer.

Improving the competitiveness of local manufacturers

The idea behind this new type of production facility came to managing director Benedikt Häring when he was unable to visit his newly born daughter and wife in hospital at the beginning of the coronavirus pandemic due to both the restrictions and a lack of protective masks. “With the concept planned for the facility, we want to allow local mask manufacturers to make their products more cheaply and sustainably in the future and therefore strengthen their competitiveness,” affirms Häring, who is also pleased about the cooperation with Landshut University of Applied Sciences: “It is important for the worlds of science and business to work together on innovations and complement each other’s expertise. That’s always a benefit for the region.”

About the project

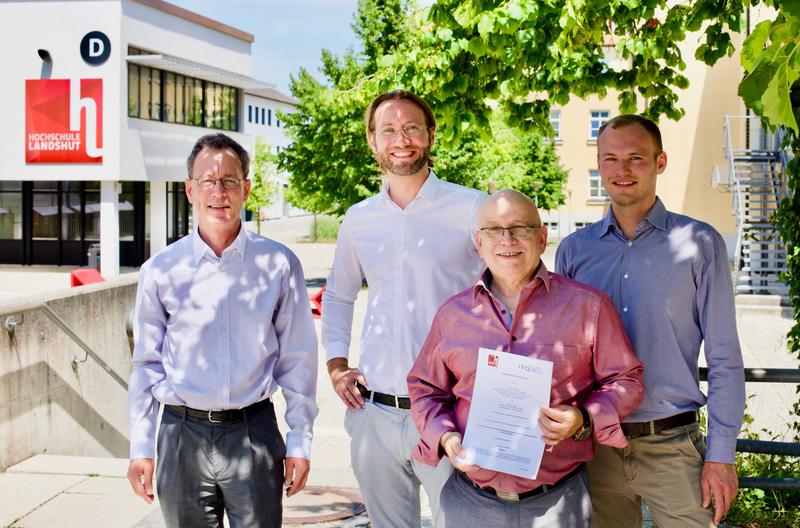

The R&D project for an innovative manufacturing plant for the production of filter media for products including protective masks is running from July 2022 to June 2024, and is being completed by Landshut University of Applied Sciences in collaboration with the Landshut-based company ringbach GmbH. David Kelnhofer from ringbach is responsible for the overall project management, and Prof. Dr. Walter Fischer, Professor for Plastics and Materials Technology, is responsible for the project management at Landshut University of Applied Sciences. The Federal Ministry for Economic Affairs and Climate Action is supporting the project with just under 400,000 euros.

Ähnliche Pressemitteilungen im idw