5th Laser Symposium Electromobility LSE'23: The perfect symbiosis of science and business

After three long years of meeting online, the industry finally convened live at the 5th Laser Symposium Electromobility LSE at the Fraunhofer Institute for Laser Technology ILT in Aachen. Around 50 interested parties accepted the invitation to hear speakers from research and industry report on progress, trends and ideas to further advance electromobilization. Highlights included a presentation by a Finnish snowmobile manufacturer, a 32-beam 100 kilowatt laser from Israel and insight from an Austrian AI expert.

"On land, on water and in the air: E-transport is on the advance everywhere," clarified Prof. Arnold Gillner, Head of Department Business Development at Fraunhofer ILT, at the Laser Symposium Electromobility LSE in Aachen this past January. It is now a matter of further reducing battery costs, which have already fallen significantly to the current level of around 100 US dollars per kilowatt hour. An integrated, sustainable approach is becoming increasingly important, starting with cobalt-free materials, climate-neutral manufacturing processes and reuse.

"It's not only important to reduce energy consumption for battery manufacturing in the long term," Gillner said. "We need to increase their energy density through new materials. What’s more, we should think about re-use wherever possible, such as using worn-out drive batteries as stationary energy storage for home use."

Cool inspiration from the Arctic Circle: battery concept with high energy density

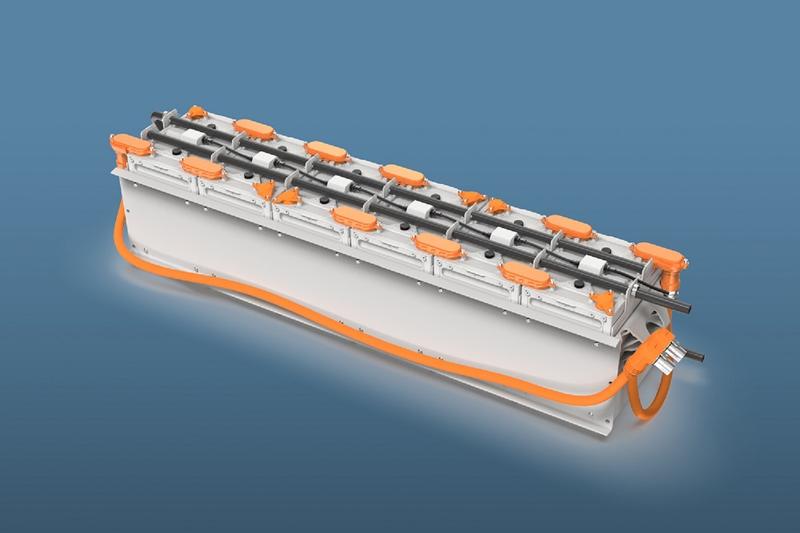

Electric mobility in perhaps one of its most exciting forms was presented by Matti Autioniemi, CEO and co-founder of the startup Aurora Powertrains from Rovaniemi, Finland, the capital of Lapland. Founded in 2017, the company is one of the first manufacturers to produce electric snowmobiles and is the world's first provider of guided tours with electric sleds. The eSled weighs 270 kilograms in the version with the largest battery capacity. The maximum range is between 40 and 100 kilometers, depending on the battery (energy capacity: 7 to 21 kilowatt hours). Since the Arctic temperatures of this region were a particular challenge, Aurora developed a waterproof and dustproof battery with IP67 classification. The modularly scalable battery has a flexible charging system for DC and AC voltage; Aurora specially designed an innovative battery management system (BMS) including an integrated heater to keep the battery at optimal operating temperature.

The developers focused on the highest possible energy density for the battery design and achieved an excellent value of more than 190 watt-hours per kilogram (Wh/kg). The Finnish company relies on lithium-ion batteries as pouch cells with 0.2 millimeter thin electrical contacts. The space-saving pouch cells are lightweight and manufactured directly in sizes specific to the application. Since there was not enough space to efficiently use ultrasonic welding equipment and the process required more vertical space, Aurora had Fraunhofer ILT develop a customized laser welding system.

Versatile application possibilities thanks to scalability and modular design

The new battery design is not only suitable for snowmobiles: Aurora can adapt the size and voltage of the bag-shaped batteries for use in electric boats, work machines or energy storage systems. "Because our battery design has such high energy density and an IP67 classification, several companies are already interested in it," explained Matti Autioniemi. "We are currently developing concepts for a Finnish electric boat company and an off-road vehicle project whose battery is designed for 120 kilowatt hours." According to Autioniemi, this concept makes it possible to economically build batteries even for larger vehicles or even trucks.

This development clearly shows that the range of applications for lasers is far from exhausted. Philippe Leopold, EMEA Sales Director at the photonics and optics company Lumentum LLC in York, UK, reported on the new PicoBlade3 laser, which operates at up to 180 watts in the near-infrared (NIR), ultraviolet (UV) and green ranges. Lumentum’s FlexBurst process fans out the main beam into 20 ultrashort-pulsed individual beams, which can be used to cut cathodes at 2 m/s and ultra-thin electrolyte foils at 20 m/s extremely quickly and precisely.

Taming the melt pool with 32 individual beams

Christian Dini, General Manager Europe of Civan Advanced Technologies Ltd. from Jerusalem, Israel, described how a melt pool can be positively influenced during welding with 32 digitally controlled individual beams from laser sources with a maximum power of 100 kilowatts. "If it can be used to weld much faster, better or more variably, it is an interesting solution," judged Dr. Alexander Olowinsky, head of the Joining and Cutting department at Fraunhofer ILT. "It remains to be seen whether the market is prepared to make the extra effort."

Because laser welding offers numerous advantages, many speakers have worked with this joining technology. Thorsten Twiehaus, a scientist at the Chair of the Welding and Joining Institute (ISF) at RWTH Aachen University, reported on his experience with laser welding under a vacuum, which has proven successful for electrical sheets, mixed joints and hairpins. For the Nuremberg-based power electronics manufacturer Semikron International GmbH, Dr. Armin Dellert reported on using green laser light for welding internal and external contacts. The development engineer particularly appreciates the larger process window.

OEM trend: Pouch passé?

EAS Batteries GmbH of Nordhausen, Germany, has joined forces with Fraunhofer ILT to develop a new laser welding system for joining large cylindrical lithium-ion cells for high-performance applications (40 to 50 ampere-hours). According to Managing Director Michael Deutmeyer, this new development is the Nordhausen-based company's response to a trend in the automotive industry, which is increasingly moving away from pouch cells in favor of cells with a solid outer shell due to their higher gas pressure stability and durability. Also for cylindrical energy storage systems, F & K DELVOTEC Bondtechnik GmbH from Ottobrunn has developed system technology that operates with cycle times of 0.7 seconds. Another advantage of the process developed with the Fraunhofer ILT is that it can be used for spot welding, as Bond Academy director Dr. Hans-Georg von Ribbeck emphasized.

Kautex Textron GmbH & Co. KG from Bonn has recently focused on laser welding batteries that can be charged and discharged particularly quickly without overheating thanks to thermal management. The manufacturer of plastic tanks, for example, opted for a laser welding process developed by Fraunhofer ILT for the current busbars. Development engineer Frank Süßemilch explained that, although it is more expensive than wire bonding, this process joins more precisely and faster, allows targeted process control and is suitable for large-scale production because of its low cycle times.

Efficient laser drying replaces gas-fired kiln system

In fact, lasers are constantly conquering new areas: The spectrum ranges from surface structuring with ultrashort pulse lasers (Fraunhofer ILT), completely stripping of paint from hairpins (Clean-Lasersysteme GmbH, Herzogenrath), removing cable insulation (SLCR Lasertechnik GmbH, Düren) all the way to the very current topic of drying. Currently, the pastes for anodes and cathodes have to dry in convection ovens that are around 100 meters long and have so far been heated almost exclusively with natural gas.

An alternative is being developed under the leadership of Laserline GmbH from Mülheim-Kärlich in the IDEEL research project (Implementation of Laser Drying Processes for Economical & Ecological Lithium Ion Battery Production). During tests at Fraunhofer ILT, the partners were able – for the first time – to dry the electrode paste on anodes and cathodes in a roll-to-roll process using a laser. Laserline manager Mathias Schlett presented a powerful infrared diode laser with 45 kilowatts of power at LSE'23, which is expected to significantly reduce energy consumption. Experts expect savings of 50 to 85 percent. At the same time, the lasers can double the drying speed and significantly reduce the size of the plant itself – the project participants are planning a belt speed of 30 meters per minute.

In all laser processes, it is important to have a better understanding of the processes in the melt pool, for example. Gehring Technologies monitors the laser welding of hairpins with X-rays, for example, while Semikron uses ultrasonic microscopy to inspect the laser welds in power electronics. Others rely on more elaborate methods such as optical coherence tomography (OCT). Christoph Spurk from the Chair of Laser Technology LLT at RWTH Aachen University even makes the trip to the synchrotron at the DESY research center in Hamburg twice a year to better understand laser processes.

Observing the processes is immensely important, says LSE co-initiator Olowinsky, and yet he points out that "everyone observes the process, but only a few regulate it – and if they do, then often from process to process. Multisensor applications are currently in vogue to retrieve measurement signals at many points. However, I am sure that the measurement process is secondary. What matters is the intelligent evaluation of the data."

Big Data analysis with the help of AI, final evaluation via "Human Intelligence"

Thomas Grünberger, Strategic Technology Developer at nLIGHT GmbH in Vienna, also addressed a major problem of all measurement methods: There is often an extremely large amount of data that has to be evaluated and assessed. In his presentation, Grünberger recommended analyzing big data, i.e. large volumes of data, with the help of machine learning. In doing so, users should be aware that unstable, uncontrolled processes such as the melt pool produce only unstable measurement data. Therefore, the final evaluation should always be done using human intelligence, i.e. by humans.

As the LSE organizer, Fraunhofer ILT not only provided a great deal of input on electromobility issues, but also offered small and medium-sized companies in particular decisive added value, in order words: helping them help themselves. Dr. André Häusler, for example, group leader of the Joining of Metals at Fraunhofer ILT, presented the planned Battery Launch Center NRW (BLC.nrw), which is already supported by partners such as Kuka, LBBZ or RWTH Aachen University.

Olowinsky explained the difference to the already existing Fraunhofer Research Institution for Battery Cell Production FFB in Münster: "Both institutions complement each other very well because Münster researches the process issues for battery cell production, while the BLC.nrw will develop the plant technology and the necessary know-how to produce a complete battery system from the cells." Häusler solicited support for the BLC.nrw in Geilenkirchen near Aachen, which is scheduled to go into operation soon: "We are looking for companies that offer equipment for the production of battery systems and potential users of the facility. So anyone who can provide us with plant technology or needs production or development capacity should contact us."

Wissenschaftlicher Ansprechpartner:

Dr.-Ing. Alexander Olowinsky

Head of the competence area joining and cutting

Telephone +49 241 8906-491

alexander.olowinsky@ilt.fraunhofer.de

Dr.-Ing. André Häusler

Group Microjoining

Telephone +49 241 8906-640

andre.haeusler@ilt.fraunhofer.de

Weitere Informationen:

https://www.ilt.fraunhofer.de/en.html

Ähnliche Pressemitteilungen im idw