Innovative lubricants revolutionize the cold forming of metals

Metals can be processed into wires by cold forming - an extremely complex process. However, the lubricants needed for this often do not meet the requirements of the end processors. As part of the KMU-innovativ project "Polyschmierung", five partners from industry and research have developed a new class of polymer lubricants that make the process significantly more environmentally friendly and economical. They are already being used successfully by industry. The project was funded with around 680,000 euros by the Federal Ministry of Education and Research (BMBF) via the Project Management Agency Karlsruhe (PTKA).

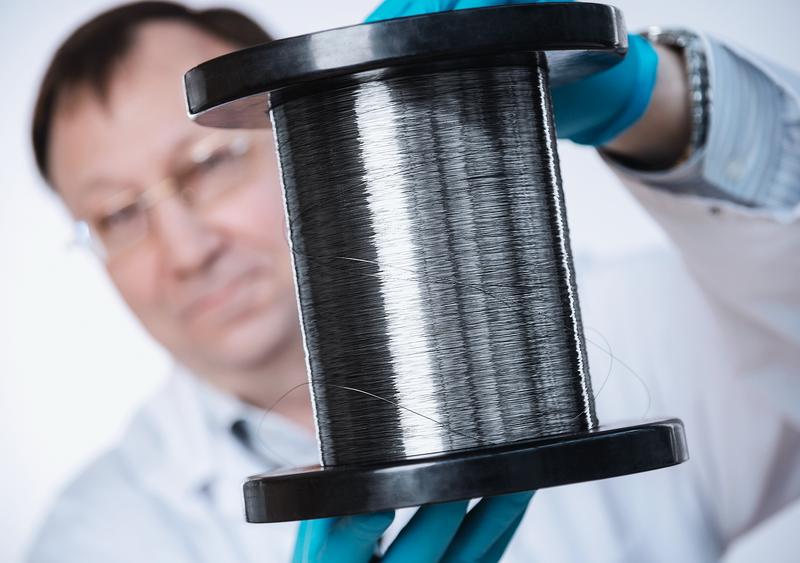

Metal springs, wire mesh and nails are products that originate from wire drawing - a process that involves intensive pre- and post-treatment and a great deal of effort. In this so-called cold forming of metals, a previously hot-rolled wire up to 50 millimetres thick is drawn through a series of drawing dies with increasingly smaller openings. In the process, the metal is stretched and its diameter reduced. Lubricants or drawing agents play a decisive role in this process: their function is to reduce friction, minimize heat generation, protect against corrosion, improve formability and extend the service life of the drawing dies. Before the lubricant is applied, however, the base metal has to be treated intensively and a carrier layer applied, which later has to be removed again at considerable expense of time and energy and with a lot of environmentally harmful chemicals. In many cases, the existing range of lubricants does not meet the requirements of end processors. The reason: in addition to the considerable effort involved, it can lead to cold welding of the wires, for example, if the pre-treatment and the drawing agent do not work.

Efficient lubrication process with sustainable polymers

"As part of the "Polyschmierung" project, we have developed new innovative polymer-based lubricants in close cooperation with industrial partners who are confronted with such challenges on a daily basis," explains Dr. Dmitry Grigoriev, chemist at the Fraunhofer Institute for Applied Polymer Research IAP, who developed the concept for the project. The requirements for the new lubricant were high: it had to be based on environmentally friendly, water-soluble polymers and reduce the amount of treatment needed before drawing. Despite thinner layers on the metal, it had to efficiently reduce the friction-related energy loss and thus significantly minimize the accompanying tool wear.

"The polymers we have developed meet all of these requirements. They are applied directly to the metal, i.e. without complex pre-treatment. As they are water-soluble, they can be easily removed afterwards with an aqueous solvent. We therefore avoid environmentally harmful, aggressive chemicals and organic solvents," says Grigoriev, describing the new lubricant class called HPPL (High Performance Polymer Lubricant).

Successful industrial cooperation: less effort, more resource savings

"The project was an absolute success," says Michael Bertzen from Chemische Fabrik Wocklum Gebr. KG, who coordinated the project on the industry side. "Thanks to the effective cooperation and the targeted selection of project team members - including a specialty chemicals manufacturer, a wire drawing company, a wire manufacturer, a plant manufacturer and a research institute - our HPPLs are already suitable for industrial use. The first wires drawn with the new lubricant have already been sold and are being used successfully," says Bertzen.

In the project, which ended in August 2023, the Fraunhofer IAP, Chemische Fabrik Wocklum, F. Brüninghaus & Söhne GmbH & Co, Fröndenberger Drahtwerk GmbH and STAKU Anlagenbau GmbH were involved.

"Thanks to the new lubricants, our drawing dies are only subjected to minimal stress. This means we no longer have to replace them as often. This saves resources and protects the environment," said Domenico Fazio, Operations Manager at F. Brüninghaus & Söhne GmbH.

STAKU Managing Director Jörg Gerhard adds: "The HPPL lubricants also offer promising possibilities, e.g. for moving towards minimal lubrication. Initial spray tests have already delivered outstanding results that have great potential for future developments."

Promising prospects for metal forming and processing

"Germany is home to just over 40 wire drawing plants for iron and steel, as well as around 120 processors, some of which carry out the drawing processes in-house and can benefit directly from HPPL polymer lubricants. We assume that more than 10 million euros per year can be saved in this way," explains Michael Bertzen. "The polymers can be individually adapted to the specific application, e.g. for alloys or wires with special coatings."

However, the potential of polymer lubricants extends far beyond wire drawing: other areas of metal forming and processing can also benefit from the development, such as tube drawing or cold forging. Here, too, lubricants play a decisive role. Chemie Wocklum can already produce sample quantities of the lubricant in the three-digit kilogram range and make them available to interested parties for industrial tests.

Ähnliche Pressemitteilungen im idw