Developers of thin-film gas sensors benefit from heated substrate platform

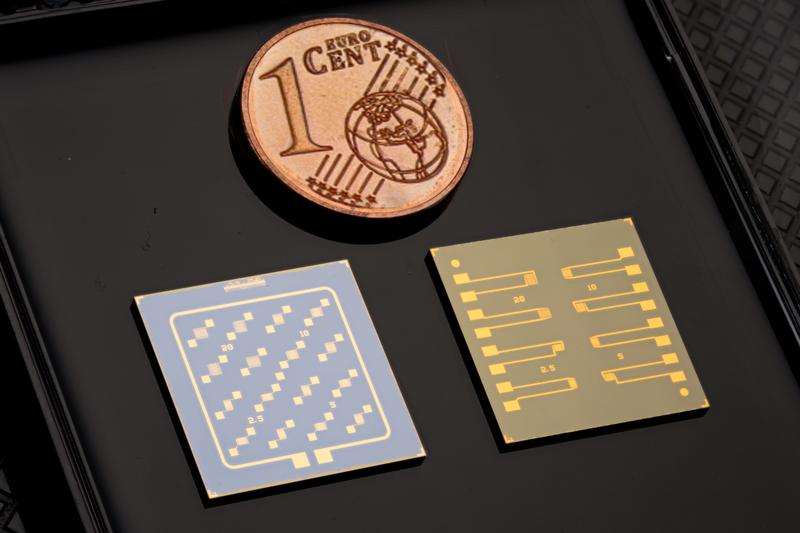

The Fraunhofer Institute for Photonic Microsystems IPMS develops and

manufactures individual heatable test chips for the characterization of new gas

sensor materials. Deposited sensing layers and their application-specific

parameters, such as sensitivity and selectivity, can thus be specifically

evaluated. Customized chip designs allow the optimal and highly accurate

characterization of these thin films.

The detection of gases such as NO2, NH3, CO, H2S or volatile organic compounds (VOC)

such as acetone, formaldehyde and methanol is of great importance for the assessment

of potential health risks.

Gas sensors based on single-component metal oxides and carbon-based materials

currently suffer from limitations such as low sensitivity in the lower ppm and ppb range

as well as limited lifetime, which prevents their widespread use as high-performance

gas sensors.

Therefore, further developments are needed to achieve electrical and thermal

properties in combination with high sensitivity, fast response, high selectivity and fast

repeatability.

In the context of such research, the characterization of sensitive layers plays a decisive

role in order to be able to produce and use the materials in a targeted manner.

Fraunhofer IPMS develops and produces conductivity and single transistor structures for

the evaluation of novel materials. These substrates can be used, for example, to

characterize the electrical properties of thin-film gas sensors. These substrates can also

be used as a basis for further product developments.

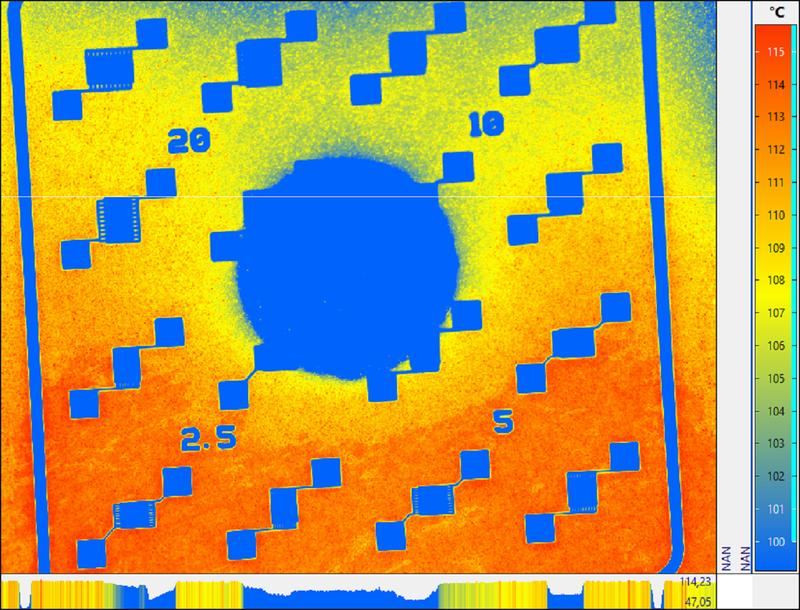

"Gas sensors often need to be operated at defined temperatures. Our substrates make

it possible to control the temperature of the layers, allowing materials to be studied

easily and effectively. This includes studying stability and drift over different time

periods. In addition, the behavior in processes can be investigated already during the

deposition. We are looking for partners to further develop the technology and can also

provide chips for measurements," explains Dr. Alexander Graf, Head of the Gas

Sensors and Systems Group.

Advantages of Fraunhofer IPMS substrates

The chip substrates produced at Fraunhofer IPMS offer high-precision structures and

high-performance materials, providing a promising basis for reproducible material

evaluation in the context of R&D questions and qualification. The substrates offer

different customized designs of the electrode structures, e.g. different channel widths

and lengths on one chip, so that the ideal parameters can be used for specific

applications.

The substrates are regularly fabricated in a clean room on silicon wafers with thermal

silicon dioxide (SiO2), with other oxides such as hafnium dioxide (HfO2) available as

dielectrics.

In sensor development, the sensitive materials determine the performance of the entire

sensor. Material and process developers can apply semiconductor layers to the

substrates by solution, chemical vapor deposition (CVD), or physical vapor deposition

(PVD). Subsequent electrical characterization allows for characterization and evaluation

based on conductivity, carrier mobility, and other performance parameters. As soon as

a gas-sensitive material comes into contact with the analyte, this leads to a change in

the electrical properties.

The substrates from Fraunhofer IPMS offer a simple way to record these changes. The

sensor materials can be evaluated with respect to sensitivity and drift and then

optimized, e.g. by adjusting the deposition parameters. Due to the wafer-level

manufacturing technology, the substrates are also an interesting basis for productoriented

development.

The test structures can be easily contacted and measured with the specially developed

prober.

----

About Fraunhofer IPMS

Fraunhofer IPMS is one of the leading international research and development service

providers for electronic and photonic microsystems in the application fields of intelligent

industrial solutions and manufacturing, medical technology and health, and mobility. In

two state-of-the-art clean rooms and with a total of four development sites in Dresden,

Cottbus and Erfurt, the institute develops innovative MEMS components and

microelectronic devices on 200 mm and 300 mm wafers. Services range from consulting

and process development to pilot production.

Wissenschaftlicher Ansprechpartner:

Dr. Alexander Graf - alexander.graf@ipms.fraunhofer.de

Die semantisch ähnlichsten Pressemitteilungen im idw