Small Membrane Fan Cools Electronic Devices Efficiently and Saves Energy

Radial or axial fans that are currently frequently used to cool electronic devices are often too large and too loud. The University of Stuttgart has now developed a membrane fan that is small and quiet. The newly developed mini membrane fan is energy-saving and can be manufactured without the use of environmentally harmful materials.

TLB GmbH has been commissioned with the commercialisation of this pioneering technology and offers manufacturers opportunities for licensing or project cooperation.

Computers, cell phones, and other electronic devices require active cooling to prevent overheating. Typically, devices in the entertainment industry and power electronics are cooled by directing an airflow to specific areas. However, commonly used radial or axial fans are often too large and noisy. As fan blades decrease in diameter, their ability to draw in air diminishes, creating limitations in size and performance. The high energy consumption and associated noise of these fans are significant drawbacks.

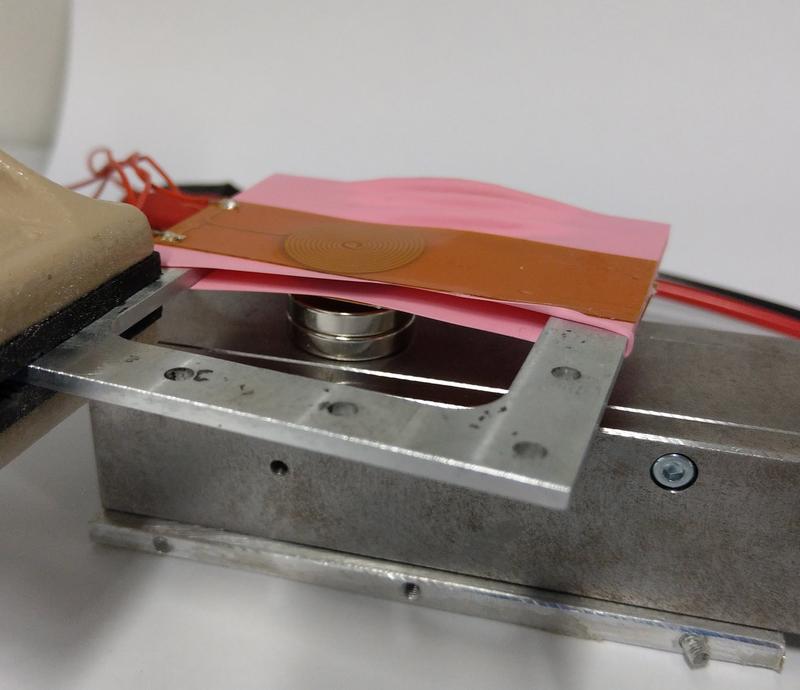

To address these issues, the Institute of Design and Production in Precision Engineering (IKFF) at the University of Stuttgart has developed a mini membrane fan that operates with low energy consumption and produces minimal noise. This innovative fan employs a targeted airflow to cool devices effectively while being energy-efficient. The mini membrane fan features an exceptionally flat design with an excitation coil thickness of less than 180 µm, making it ideal for cooling power dissipators. It achieves a high air velocity of over 2.5 m/s, allowing effective cooling even at greater distances from the fan. The energy consumption ranges from only 25 to 75 mW.

Targeted ventilation is essential for compact devices containing internal heat sources, such as drives or power electronics. These devices are cooled through convection and heat conduction via directed airflow. Additionally, this cooling method is suitable for hotspot cooling in hard-to-reach areas of a device.

The membrane fan comprises a permanent magnet, two elastic membranes, and two opposing excitation coils attached to the membranes. When a sinusoidal current flows through the coils, the membranes are alternately pulled downwards and upwards, causing the membrane opening to open and close, resulting in a forward airflow. This design produces minimal noise, eliminating the typical fan noise (less than 30 dBA).

The flexible design of this electrodynamic system allows for direct application of the coils to the membrane, enabling a very flat installation. If the membranes are made of magnetic foils, the fan's service life is extended during continuous operation.

The invention has been filed for patent protection (DE 102021110218.9 pending, DE 102019004272A1 pending, DE 102020128181A1 pending). The Technologie-Lizenz-Büro (TLB) GmbH is supporting the scientists and the University of Stuttgart in the patenting and commercialization of this innovative development. TLB has been commissioned to commercialize this groundbreaking technology and offers manufacturers opportunities for licensing or project collaboration. Further development with project partners at the institute is desired.

For additional information, please contact: Innovation Manager Monjur Islam (mislam@tlb.de).

Wissenschaftlicher Ansprechpartner:

Prof. Dr.-Ing. Bernd Gundelsweiler, Universität Stuttgart, Institut für Konstruktion und Fertigung in der Feinwerktechnik

Weitere Informationen:

https://www.technologie-lizenz-buero.com/

https://www.ikff.uni-stuttgart.de/en/

Ähnliche Pressemitteilungen im idw