Digital and efficient: LZH develops multi-laser beam welding process for maritime manufacturing

Laser Zentrum Hannover e.V. (LZH) is researching ways to make welding thick plates in shipbuilding more reliable. The scientists are developing a multi-laser beam welding process with customized beam shaping and a "Digital Twin"-based integrated quality assurance system.

Welding in the thick sheet metal sector is challenging due to the high penetration depths required. Researchers at LZH aim to facilitate welding of thick-walled components in the 15 mm to 30 mm range with an innovative multi-laser beam welding process that includes integrated quality assurance.

Digital Twin enhances process monitoring

With integrated quality assurance, the scientists aim to ensure consistent, defect-free, and high-quality welds. They will combine various sensors to capture features related to the characterization of welds, such as weld reinforcement, seam width, and distortion. Based on this data, they will develop an adaptive welding process control and an integrated quality assurance system that can classify weld quality as "acceptable" or "not acceptable."

Additionally, LZH will transfer the sensor data from the quality assurance system into digital twins that digitally represent the process and the weld seam based on various measurement data. With the digital twin, researchers can document and track the process. The goal is to reduce overall error rates in automated welding in shipbuilding, minimize necessary component inspections in production, and make the manufacturing process more economical.

Multi-laser beam welding conserves resources and reduces manufacturing costs

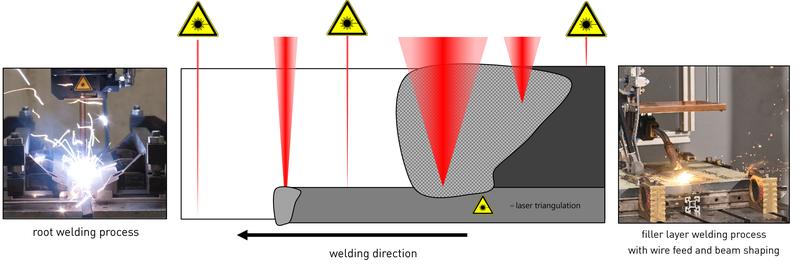

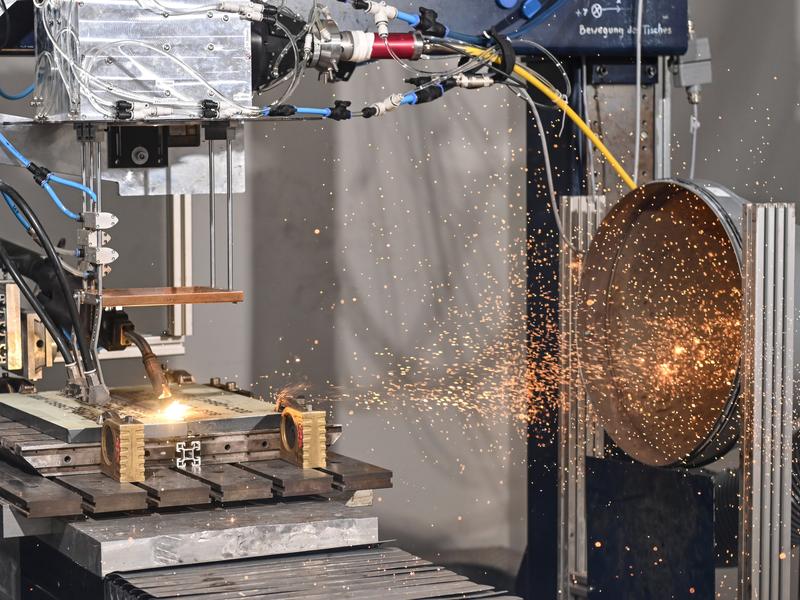

To weld with high quality and without cracks even with material thicknesses of up to 30 mm, researchers are developing a multi-laser beam welding process for thick plates. They will combine three laser beam sources into a parallel root and filler layer welding process. By customizing beam shaping, they can precisely control the characteristics of the molten pools, temperatures, solidification, and microstructure to prevent hot cracks.

The goal is that the one-run process developed, with welding depths beyond the current state of the art, will significantly reduce the number of weld passes, manufacturing time, and consumption of filler material and shielding gas. This will conserve resources and reduce manufacturing costs. Both the processes and the innovative system technology being developed are intended to be transferred to industrial manufacturing plants in the maritime sector.

About DIGIMAR

The subproject "Digital Twin-based Quality Assurance and Adaptive Process Control in Multi-Laser Beam Welding" is part of the joint research project "Multi-Laser Beam Welding Processes with Digital Twin-based Quality Assurance for Maritime Applications on Thick Plates" (DIGIMAR). Project partners include, in addition to LZH, MEYER WERFT GmbH & Co. KG (system technology integration and process development) and Laserline GmbH (multi-laser beam source and combined processing optics). DIGIMAR is funded by Project Management Jülich with funds from the Federal Ministry for Economic Affairs and Climate Action (grant number 03SX617C).

Weitere Informationen:

https://www.lzh.de/en/press-releases/2024/digital-and-efficient-lzh-develops-multi-laser-beam-welding-process-for-maritime-manufacturing

Ähnliche Pressemitteilungen im idw