International alliance for green hydrogen

The fifth Laser Colloquium Hydrogen - LKH2, organized by the Fraunhofer Institute for Laser Technology ILT, will take place on September 10 and 11, 2024, Once more it will focus on promoting sustainable networking since no state, no company, no research institution can manage the transition to sustainable hydrogen production alone. That is why numerous experts from industry and research will again meet in Aachen to exchange ideas and develop solutions together. One of the highlights of this year's congress will be the presentation of the German-Australian HyGATE project.

"The processes of producing hydrogen and compressing, transporting and converting it back into electricity or mechanical energy are still far too inefficient," explains Dr. Alexander Olowinsky, head of the Joining and Cutting department at Fraunhofer ILT and organizer of the LKH2.

Increasing the efficiency of hydrogen processes is one of the top themes of the LKH2 and is the common thread running through all the presentations. The variety of topics covered in the almost 20 presentations shows the range of highly efficient laser processes for the entire hydrogen production process chain. The presentation by Robert McConville, principal manufacturing engineer at Hysata Pty Ltd from Unanderra, Australia, near Sydney, will certainly be of particular interest to participants. According to the company, it aims to supply the world's cheapest green hydrogen in the not-so-distant future.

The chances are good, as a spin-off from the University of Wollongong has developed a capillary electrolyzer in which small capillaries distribute the water evenly. This electrolyzer achieves a remarkably high system efficiency of 95 percent (41.5 kWh/kg). The alkaline electrolyzer requires considerably less energy to produce one kilogram of hydrogen than the best commercial water electrolyzers currently available. The efficiency of the Hysata electrolyzer, which has been proven in practice, is above the efficiency target (42 kWh/kg) set by the International Renewable Energy Agency (IRENA) for the year 2050.

Pooling expertise from Germany and Australia

The next step is to start efficient large-scale production as part of the "German-Australian Hydrogen Innovation and Technology Incubator (HyGATE)" funding initiative. Australia and Germany have been building the world's first supply chain for sustainable hydrogen since June 2023. In Aachen, Hysata's lead engineer McConville will also explain the role of German production technology in the entry into the efficient production of electrolyzers. His talk is sustainable in two ways: He is not traveling to Aachen by plane, but is giving his talk online at LKH2 to report on the joint approach. "When we talk about sustainability and the energy supply of the future, we can't send a speaker halfway around the world to give a lecture here," explains Olowinsky.

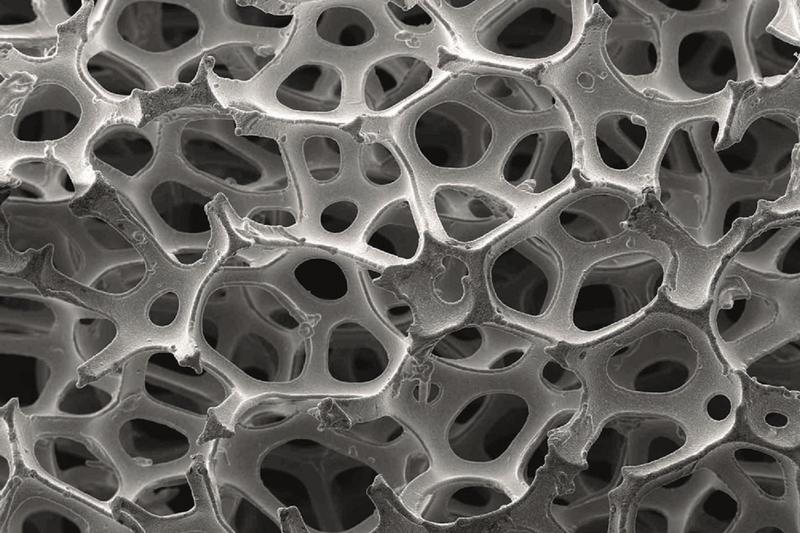

The laser is the focus of McConville's presentation: Fraunhofer ILT is developing laser-based processes and systems in a sub-project on production technology – for example, for processing metal foam electrodes. This development by the Dresden-based Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM increases the reaction surface and thermal conductivity, thereby increasing efficiency.

From metal plate production to laser-induced nanofoams

Other equally exciting paths to a green hydrogen future can be seen in the other contributions from industry and research: The speakers will explain how to get started with the large-scale production of bipolar plates and fuel cells, how optimal coatings can be created and how complex laser processes monitored. The variety of topics covered by the 20 or so presentations illustrates the range of laser technology for the entire hydrogen production process chain.

This becomes clear from a brief look at the presentations: Stefan Kaiser from ANDRITZ Kaiser GmbH, for example, will explain the advantages of high-precision beam deflection in the laser microwelding of bipolar plates. Stoyan Stoyanov from Fraunhofer ILT will show participants how these metal plates can be cut using ultrashort pulse lasers. Eike Hübner from the Fraunhofer Heinrich Hertz Institute HHI will explain why nanofoams produced with the laser (laser-induced nanofoams, LINF) are particularly suitable for use in catalytic converters. David Janssens from Siemens will point out how tunable diode laser absorption technology (TDLAS) and the AI-based management of analysis systems help to produce high-quality green hydrogen with high throughput.

A key to greater efficiency

Participants can also explore the current state of research during laboratory tours. With the HydrogenLab, Fraunhofer ILT has created optimal conditions for optimizing the fuel cell from the basics to series production. The HydrogenLab is designed for interdisciplinary collaboration and offers space for public projects and industrial cooperation in order to achieve synergies. Fraunhofer scientists conduct research here on the cost-optimized and demand-oriented series production of fuels and accelerate the rollout in industry and society. The 300 square-meter HydrogenLab has laser technology test facilities for the production of metallic and compound bipolar plates. It provides users with systems for structuring with ultrashort pulse lasers, laser-based coating and high-speed welding and cutting. Test benches test the hydrogen tightness and efficiency of the laser-produced components.

How the industry should respond to criticism of the efficiency of hydrogen processes is one of the main questions that the fifth LKH2 in Aachen aims to answer. Dr. Olowinsky explains: "We are demonstrating how laser technology can improve the efficiency of hydrogen production. It is the decisive key, the most important tool for optimizing the processes and components."

LKH2 - Laser Colloquium Hydrogen

On September 10 and 11, 2024, interested parties can find out about and exchange information on the current state of research in the field of laser-based hydrogen production at the long-standing insider event of the hydrogen community in Aachen. Here you can find the program of the Fraunhofer ILT event: https://s.fhg.de/d52

HyGATE: German-Australian hydrogen alliance

The HyGATE funding measure was developed by the Federal Ministry of Education and Research (BMBF) together with the Australian Renewable Energy Agency (ARENA). Germany is providing up to €39.6 million to fund the bilateral projects, while Australia is providing up to AU$50 million (€32 million). In Australia, ARENA is coordinating the cooperation on behalf of the Australian government (Department of Industry, Science, Environment and Resources, DISER); in Germany, the project management organization Jülich (PtJ) is responsible for coordination on behalf of the BMBF. The "High-Efficiency 'Capillary-fed' Electrolyzer Pilot Project (CFE Pilot)" under the consortium leadership of the Australian company Hysata Pty Ltd started in June 2023 as one of four projects that Australia is funding with around AU$8.9 million (€5.5 million) and Germany with more than €6 million.

Wissenschaftlicher Ansprechpartner:

Dr.-Ing. Alexander Olowinsky

Head of Department Joining and Cutting

Fraunhofer Institute for Laser Technology ILT

Steinbachstr. 15

52074 Aachen

Phone +49 241 8906-491

Email: alexander.olowinsky@ilt.fraunhofer.de

Weitere Informationen:

https://www.ilt.fraunhofer.de/en

Die semantisch ähnlichsten Pressemitteilungen im idw