Laser deburring increases component quality

Burrs on cut and punched edges of sheet metal increase the risk of injury and can often damage cables and scratch surfaces. For this reason alone, it makes sense to deburr such edges. If this is done by laser, not only can edges be selectively reinforced, but the fatigue strength of the components can be increased and the tendency to forming cracks reduced. The Fraunhofer Institute for Laser Technology ILT in Aachen will be presenting state-of-the-art laser deburring processes at the EuroBLECH trade fair in Hanover from October 22 to 25, 2024. Interested parties can also find out more about laser polishing of sheet metal at the stand in Hall 27 | D142.

In the automotive industry, laser deburring has become established in some large-scale production processes over the last decade. "But the potential of this technology is far from exhausted," says Dr. Edgar Willenborg, expert for laser polishing and laser deburring at the Fraunhofer ILT. Deburring sheet metal in particular is uncomplicated, improves component quality – and thanks to processing speeds of up to twelve meters per minute – is also fast and efficient. To get these messages across to experts, the Aachen-based institute's Polishing Group, headed by Willenborg, will be exhibiting laser deburring processes at EuroBLECH in Hanover for the first time in October 2024.

A long list of benefits

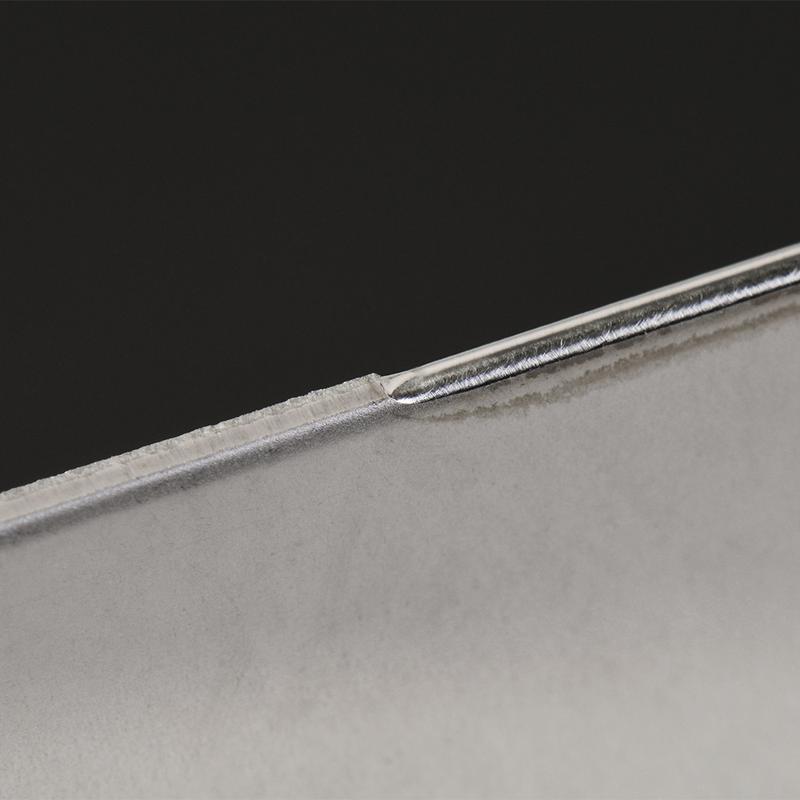

In principle, deburring is necessary to minimize the risk of injury. In addition, sharp burrs on cut and punched edges often damage cables and scratch surfaces. Until now, mechanical processes have usually been used to remove burrs. However, research by Fraunhofer ILT shows that laser processes have clear advantages here. The process itself is uncomplicated. "The laser focus must hit the front of the sheet edge and cover it completely," explains Willenborg. There, the focused beam of light briefly melts the metal edge and burr. The surface tension then causes the liquid metal to smooth itself out. This creates a rounded edge. "Alternative process control makes it possible not only to round off the edge, but also to strengthen it in a targeted manner," says the expert. To accomplish this, the institute has increased the power of the laser; this additional energy input melts more material, which is placed around the edge like a reinforcing round seam.

The smooth, rounded edges prevent cuts as well as damage to cables and surfaces. But the laser process can do more: It leaves defect-free edges. "This results in clear advantages in the fatigue strength and mechanical forming behavior of the sheet metal components," emphasizes Willenborg. Tests with high-strength steel show that its fatigue strength increases by 220 percent as a result of laser deburring. At the same time, the degree of deformation increased by 240 percent. Until then, the edge crack can be avoided. The expert explains the positive effects as follows: Laser melting eliminates any micro-defects in the edges caused by mechanical processing. Such pre-damage, which is invisible to the naked eye, is often where crack formation begins.

Laser deburring is fast, clean and inexpensive

According to Willenborg, another major advantage of laser deburring over mechanical processes is that no grinding dust is produced. Instead of removing it, the process only briefly melts the excess material, thus making it comparatively easy to integrate laser deburring into existing process chains and production environments. Where integration is practicable, the benefits quickly become apparent. "Laser deburring is particularly advisable for highly stressed components," he emphasizes. He cites chassis parts as an example: The increased fatigue strength in the edge area allows their manufacturers to design them to be thinner and therefore lighter and ultimately more fuel-efficient.

When it comes to formed 3D sheet metal components, the laser can be mounted on robots. One advantage here is that fiber-coupled diode lasers are already in use for deburring. According to Willenborg, the standard lasers in the near-infrared wavelength range are also inexpensive and readily available.

From the conference in Aachen to the trade fair in Hanover

The Fraunhofer expert invites interested parties to find out more about the possibilities of laser deburring and the latest processes for laser polishing sheet metal at EuroBLECH 2024 in Hall 27, Stand D142.

But the trade fair will not be the only highlight in October. "Just one week earlier, on October 15 and 16, 2024, the 6th Conference on Laser Polishing - LaP will take place at the Fraunhofer ILT in Aachen," he says. The international scientific conference offers ample opportunity for in-depth technical discussions on all aspects of laser polishing and laser deburring.

Wissenschaftlicher Ansprechpartner:

Dr. Edgar Willenborg

Head of the Polishing Group

Phone +49 241 8906-213

edgar.willenborg@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstrasse 15

52074 Aachen

www.ilt.fraunhofer.de

Weitere Informationen:

https://www.ilt.fraunhofer.de/en.html

https://www.ilt.fraunhofer.de/en/fairs-and-events/fairs/2024/euroblech-2024.html

https://www.ilt.fraunhofer.de/en/fairs-and-events/events/2024/lap-2024.html

Die semantisch ähnlichsten Pressemitteilungen im idw