TU Freiberg develops aluminium battery with innovative electrolyte

Energy storage systems of the future must be cost-effective and sustainable. To achieve this, it is crucial that the materials used are both readily available and recyclable. A research team at TU Bergakademie Freiberg has now made significant progress in the development of an aluminium battery that meets these requirements. The battery consists of aluminium as the anode, graphite as the cathode and a new type of polymer-based electrolyte developed at the university. The validation of the battery prototype for industrial production will be funded by the Saxon Ministry of Economic Affairs and the European Regional Development Fund (ERDF) until the end of next year.

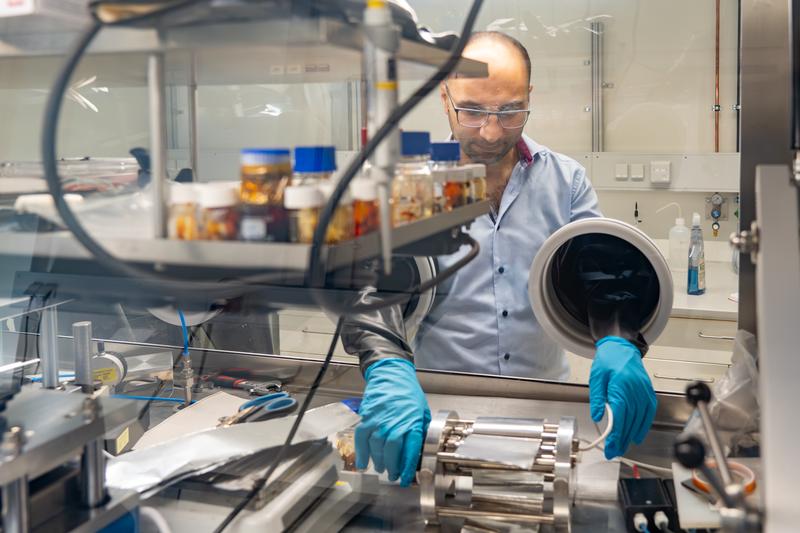

Wearing long black rubber gloves, Amir Mohammad reaches into a glovebox to open a jar containing a honey-coloured polymer. Using a spatula, he carefully applies it to a thin aluminium foil. Finally, he coats the aluminium foil with the polymer in a so-called calender with heatable rollers. "That's already two thirds of the battery," explains Amir Mohammad. The aluminium foil serves as the anode, while the polymer layer forms the electrolyte. Combining this with a graphite cathode creates a single cell for the prototype of the aluminium-polymer battery. The first prototype, consisting of a so-called "stack" with 10 cells, will be able to store around 1 watt hour (Wh) of energy.

The funding from the Sächsische Aufbaubank as part of the validation funding programme of the Saxon Ministry of Economic Affairs is now taking this battery to the next level: "The aim of further development is a storage capacity of 10 kilowatt hours (kWh), which corresponds to the average daily production of a photovoltaic system on the roof of a detached house," explains the research associate at the Institute of Experimental Physics. This makes the new type of aluminium-polymer battery an option for use as a stationary electricity storage system, especially for private photovoltaic systems.

Newly developed polymer solid electrolyte ensures efficient production

The team is paying particular attention to the electrolyte solution between the anode and cathode: "We have developed a polymer electrolyte based on an ionic liquid for this purpose. This is a mixture of triethylamine hydrochloride and aluminium chloride, which together with polyamide form a solid network. Compared to traditional liquid electrolytes, this solid electrolyte offers numerous advantages: It cannot leak, is resistant to moisture and oxygen and reduces corrosion. It also replaces the usual separator layer, which makes the battery safer and cheaper to produce," explains project team member Oliver Schmidt.

The next step for the team is to test the processing of the materials and the production of the aluminium-polymer battery in a roll-to-roll production system. The two researchers expect reliable results on the utilisation of their innovative battery prototype by the end of 2025.

Energy storage: What comes after lithium?

"We need new energy storage systems for the electrification and thus flexibilisation of energy-intensive technologies," explains Prof. Dr Dirk C. Meyer, Director of the Institute of Experimental Physics and spokesperson for the Centre for Efficient High-Temperature Material Conversion at TU Bergakademie Freiberg. "The aluminium-polymer battery is a promising alternative to lithium-ion batteries, which my team has been researching intensively for around ten years and which is now being tested with a view to industrial production and application."

The Saxon Ministry of Economic Affairs is funding the transfer of the research results into application with a total of €241,562 until November 2025.

Wissenschaftlicher Ansprechpartner:

Prof. Dirk Meyer, dirk-carl.meyer@physik.tu-freiberg.de

Die semantisch ähnlichsten Pressemitteilungen im idw