Green aerospace with 3D printing

The European Commission's targets are ambitious: the ReFuelEU Aviation Regulation stipulates a 60 percent reduction in CO₂ emissions from aviation by 2050 compared to 1990 levels. A comprehensive EU Space Law (EUSL) is also planned, including rules on the sustainability of space activities. Aerospace companies are receiving support from the Fraunhofer Institute for Laser Technology ILT in Aachen and its new additive manufacturing processes, which significantly reduce the ecological footprint and reduce production costs.

"How can aviation be made greener?" asks Luke Schüller, research associate at Fraunhofer ILT, in a technical article. He provides the answer: by using lightweight construction, 3D printing and new high-performance materials to meet strict political climate protection requirements.

The LPBF (laser powder bed fusion) process, in which metal powder is fused layer by layer with the laser beam, plays a key role. This method enables users to produce complex and high-strength components that are not only lighter but also more resistant – crucial properties needed for the aviation of tomorrow.

Teamwork with material manufacturers: special powders for the future of hydrogen

Fraunhofer ILT is developing special powders as part of the TIRIKA research initiative (Technologies and Innovations for Resource-saving, Climate-friendly Aviation) of the Federal Ministry for Economic Affairs and Climate Action. The initiative focuses on using hydrogen as an emission-free energy source for aviation. Together with material manufacturers, the experts have developed powders that meet the high requirements of the aviation industry for hydrogen engines. The experts have also developed LPBF processes for materials that are commercially available and finally validated them in cooperation with the partners using various test procedures.

"Since targeted adjustments have been made in the LPBF process, we can now achieve a relative component density of over 99.5 percent and a high build-up rate of more than 100 cm³/h," explains Schüller. Not only are the aluminum alloys lightweight, but they have high-strength. Furthermore, they are resistant to hydrogen, an element that can cause embrittlement and material fatigue at high temperatures and pressures. This makes these alloys ideal candidates for use in future emission-free hydrogen engines. What's more, thanks to the uniform laser melting process, the new special powders make it possible to generate complex geometrical forms and functional structures that cannot be made using conventional processes such as casting or forging.

Electronic detection sensor for 0.4 millimeter particles

During the production process, a precise sensor system detects artefacts down to a size of 0.4 millimeters directly in the powder bed and in the melting process. This minimizes time-consuming downstream inspections and significantly increases production efficiency.

However, advanced processes not only influence the quality and efficiency of production, but also their ecological footprint. Fraunhofer ILT uses life cycle assessment (LCA) to evaluate the environmental friendliness of additive manufacturing processes. This involves looking at the entire life cycle of a component – from raw material procurement to production and recycling. "For us, the life cycle assessment is an indispensable tool for evaluating the environmental impact of products over their entire life cycle and identifying sustainable alternatives," says Dr. Tim Lantzsch, head of the Laser Powder Bed Fusion department at Fraunhofer ILT. However, in order to design this comprehensive process effectively, research needs to acquire high-quality and meaningful data at an early stage of the digital value chain.

Triple plus for complex process

Three important arguments speak in favor of this initially very laborious path: Firstly, this data enables researchers to design start-up processes for new products faster and more efficiently. Secondly, they support researchers in evaluating quality, costs, energy and resource consumption in the production cycle. Thirdly, they contribute to greater transparency in the processes and, thus, to optimizing the entire production chain.

The results of the LCA analyses show that, despite the comparatively high energy consumption during the LPBF process, the ecological footprint of additive manufacturing is significantly smaller than that of conventional production methods. 3D printing is, therefore, particularly suitable for repairing components because it minimizes material losses and conserves resources.

Additive processes are also the focus of the EU project ENLIGHTEN (European iNitiative for Low cost, Innovative & Green High Thrust ENgine Project), which was launched in November 2022 and is managed and coordinated by the Ariane Group. Since the start of the project, 18 partners from eight European countries have had one goal: to develop cost-effective and environmentally friendly rocket engines that work with bio-methane and green hydrogen, among other things. The new eco-engines are intended to power the next generation of European reusable rockets and thus strengthen Europe's competitiveness in the global aerospace sector.

Faster and cheaper into space with LMD

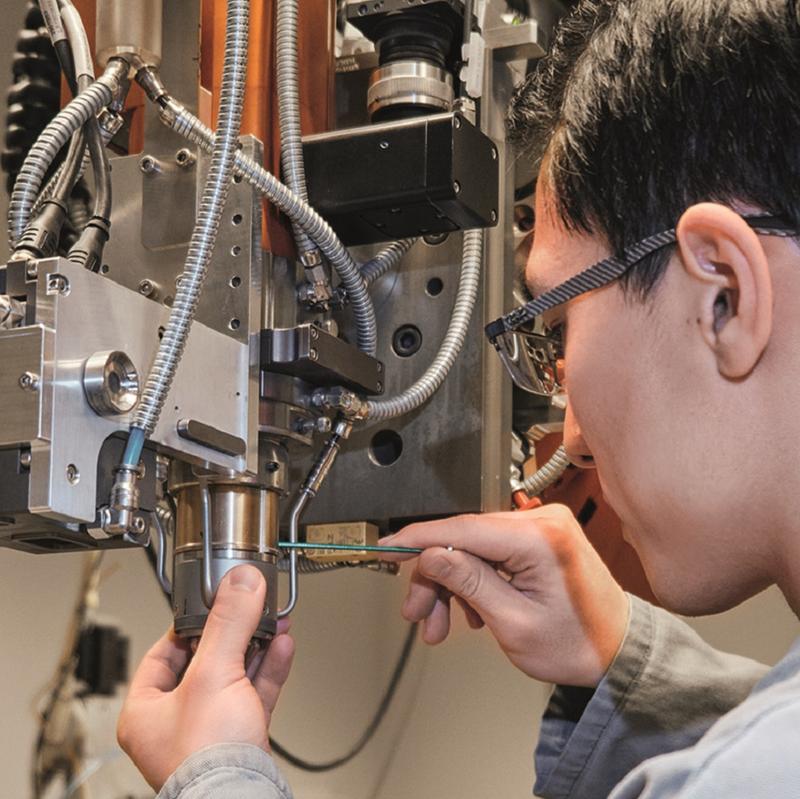

This is where the Aachen Institute comes into play. As part of the project, experts from the Additive Manufacturing and Repair LMD group are developing a process to manufacture rocket components more efficiently and precisely using laser material deposition (LMD). "The special thing is that we are using LMD to drastically improve the speed and cost-effectiveness of manufacturing new types of rocket nozzles," explains Min-Uh Ko, group leader of Additive Manufacturing and Repair LMD at Fraunhofer ILT. "Apart from its large installation space, the design under investigation has exceptionally filigree and thin-walled cooling channels that can only be generated with great effort using conventional manufacturing routes." The goal by the end of the project in October 2025: LMD production of a nozzle for use in the next generation of rockets in the Ariane program and construction of a true-to-scale demonstrator.

One argument against conventional methods is the usual: Since no one company can offer all the different process steps in a local production facility, the components have to be transported to several locations. The resulting process chain leads to time-consuming and costly production, which often takes several months. Jochen Kittel, project manager of the ENLIGHTEN project at Fraunhofer ILT: "With our process technology, which saves many individual process steps, we can not only substantially reduce costs. At the same time, we are also significantly shortening the production time of a rocket nozzle."

A complete grip on the process

The experts are taking an integrated approach to the project: By its end, they plan on developing a reliable, controlled manufacturing process including quality assurance for series production. An inline system will use sensors to monitor the entire process, detect and rectify process anomalies and ensure consistently high component quality. Min-Uh Ko: "Once we have successfully developed the process and the demonstrator, it will mark a breakthrough. With our results, we can enable the industry, as a supplier to the aerospace industry, to produce equally large, complex and filigree structures on their own systems via LMD in the future."

Formnext 2024

Visit us from November 19 to 22 in Frankfurt am Main at the Fraunhofer joint booth D31 in hall 11 and learn more about the possibilities of AM.

Wissenschaftlicher Ansprechpartner:

Dr. Tim Lantzsch

Head of Laser Powder Bed Fusion Department

Phone +49 241 8906-193

tim.lantzsch@ilt.fraunhofer.de

Min-Uh Ko M. Sc.

Head of the Additive Manufacturing and Repair LMD Group

Phone +49 241 8906-8441

min-uh.ko@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstrasse 15

52074 Aachen

www.ilt.fraunhofer.de

Weitere Informationen:

https://www.ilt.fraunhofer.de/en.html

https://www.ilt.fraunhofer.de/en/fairs-and-events/fairs/2024/formnext-2024.html

Ähnliche Pressemitteilungen im idw