Project DioHELIOS launches as part of BMBF Funding Program “Fusion 2040”

High-power laser diodes are a key component for fusion power plants of the future. The joint project DioHELIOS sets out to boost their power and efficiency to a new level and to develop approaches for their automated mass production. This is because diode laser modules are required in large quantities for climate-neutral energy generation through laser-based inertial confinement fusion. Several companies and institutes are working together in the BMBF-funded project: ams-OSRAM, the Ferdinand-Braun-Institut, Leibniz-Institut für Höchstfrequenztechnik (FBH), the Fraunhofer Institute for Laser Technology ILT, Jenoptik, Laserline and TRUMPF.

Schramberg, October 2024. For the first time, in December 2022, US researchers succeeded in obtaining more energy from a fusion reaction of the hydrogen isotopes deuterium and tritium than the large laser needed to ignite the plasma had put in. Since then, the National Ignition Facility (NIF) at the Lawrence Livermore National Laboratory (LLNL) in California has repeated the fusion several times with increasing energy gain. In recent experiments, the fusion released more than twice as much energy as the laser emitted.

The proof of principle – that laser-ignited inertial confinement fusion works – has triggered a new dynamic in fusion research worldwide. This is because fusion not only decouples energy generation from the carbon cycle, meaning it does not emit any greenhouse gases, but is also based on an almost unlimited supply of fuel, is inherently safe and can supply energy at maximum reliability while being able to run 24/7.

BMBF funding program Fusion 2040 launched

The Federal Ministry of Education and Research (BMBF) recognized the new dynamic early on and set up the “Fusion 2040 - Research on the Way to the Fusion Power Plant“ funding program in March 2024. “We now need to use our home advantage. Germany already has unique expertise in fusion research that is respected worldwide,“ explained Bettina Stark-Watzinger, Federal Minister of Education and Research, at the program kickoff, “and our research institutes and supplier industry are both among the international leaders. We must consistently develop the results of domestic basic research in order to position Germany at the forefront of the global race.“

This research is now picking up speed thanks to the joint project DioHELIOS within the “Fusion 2040” funding program. It brings together a broad consortium from the photonics industry and research to advance a key component for fusion power plants of the future: high-power diode laser modules. These are needed as pump sources for the high-energy lasers that compress plasma from hydrogen isotopes at a pressure of around 300 gigabars to an extreme extent, and ignite it at temperatures of around 150 million degrees Celsius, ten times hotter than inside the sun. In the Californian test facility, this task is assigned to the world's largest and highest-energy laser. In an area the size of three football fields, 192 beam paths generate over two megajoules of energy per pulse. Peak power is almost 500 terawatts. The system operates in the ultraviolet wavelength range at 351 nanometers with pulse durations of around 10 nanoseconds. Conventional flash lamps are used as the pump source.

Key components for fusion power plants

Planned in the 1990s with the state-of-the-art technology available at the time, the test facility was not designed for efficient energy generation, but for basic fusion and plasma research. The plant design is unsuitable for commercial power plants because the laser needs several hours to cool down after each shot. In a power plant, on the other hand, repetition rates of 10 to 20 ignitions per second are required. The efficiency of the entire laser system must also be immensely increased, which, according to the current state of the art, can only be achieved with laser diodes specifically tuned to the absorption lines of the amplifier medium instead of broadband emitting flash lamps. However, today's diode laser pump modules do not meet the requirements of commercial power plants: Neither do they achieve the necessary performance (efficiency, irradiance and lifetime combined), nor can enough of them be produced at a reasonable price. The demand for diode laser bars – the semiconductor-based basic components of the pump modules - for a single power plant already exceeds their current global annual production.

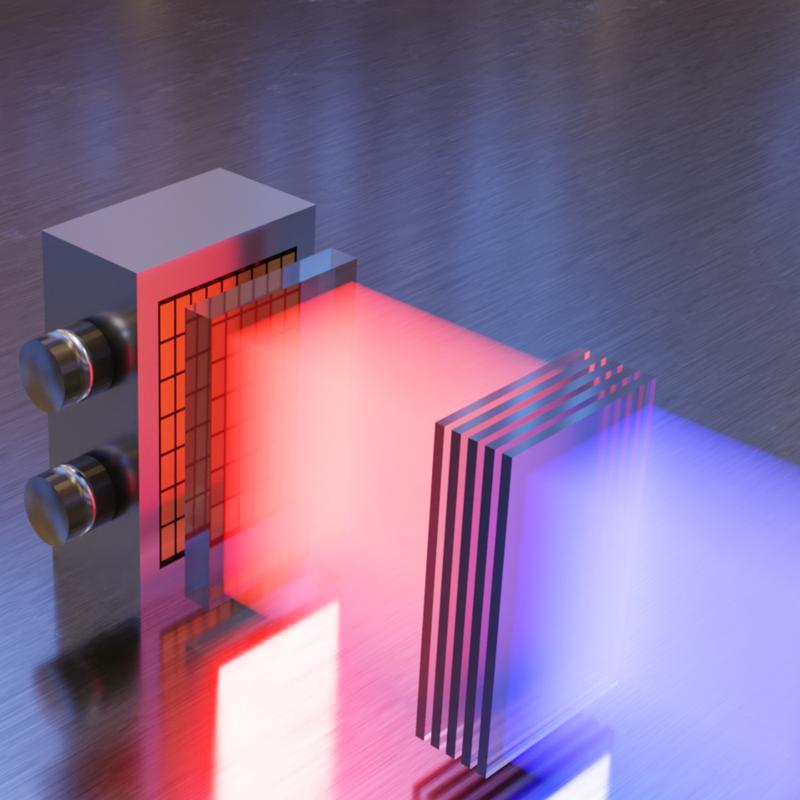

For this reason, the DioHELIOS project (Diode Laser Pump Sources for High-Energy Lasers in Fusion Power Plants) must break new ground in the development of pump modules, which are absolutely essential to make laser-based fusion power plants possible. In general the laser pulses for fusion are generated with energies in the nano-joule range from a pulsed fiber laser. As they pass through several amplifier stages, their energy level is gradually ramped up into the double-digit joule range. To pump them into the kilojoule range, the laser pulses repeatedly pass through 20 to 40 cm large, specially doped glass or crystal plates, where the spatially, temporally and spectrally precise energy provided by the diode laser modules amplifies them. Depending on the system design, the pulses pass through this in parallel in 200 to 400 beam paths before they reach the fusion chamber, where they are bundled into a high-intensity megajoule beam and ignite the target.

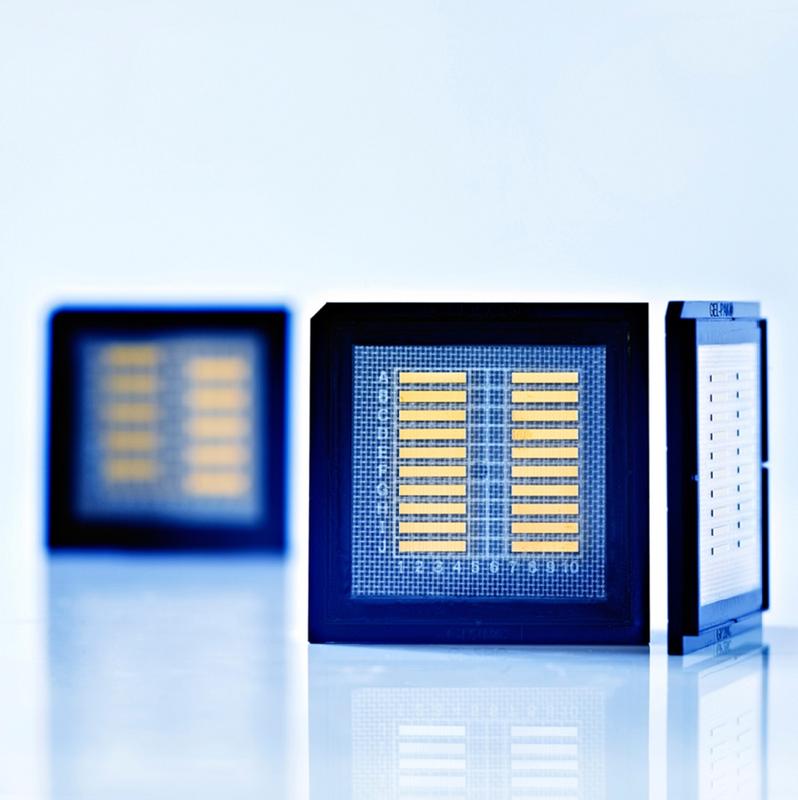

This amplification needs customized pump modules developed specifically for the requirements of inertial confinement fusion. Not only must their pulse energy increase by a factor of 50 compared to today’s technology, but efficiency must also be improved at the same time. Moreover, significantly more homogeneous and stable spectral properties are required as are diode laser modules that can be mass produced in an automated process at a cost of less than one cent per watt of power. Last but not least, the hardware should function around 30 years at repetition rates of around 15 hertz.

Ambitious technological objectives

The six DioHELIOS consortium partners – two research institutes and four industrial companies – will focus their research on these objectives. A seventh partner is associated with the laser fusion start-up Focused Energy from Darmstadt. Jenoptik, ams-OSRAM and the Ferdinand-Braun-Institut (FBH) will contribute their expertise as leading manufacturers and developers of laser diodes and drive forward new approaches for semiconductor lasers. Fraunhofer ILT will support them by designing and optimizing the diode laser bars with its specially developed SEMSIS software. The aim is to significantly increase the output power of the chips while ensuring they can be manufactured industrially at the required cost level and resource efficiency. In the case of diode lasers for fusion power plants, the spectral distribution of the laser beam needs to be as stable as possible. The consortium is pursuing new design approaches for this as well as for increased light yield by using so-called multi-junction concepts: They aim to significantly increase the yield in the electro-optical conversion of electrons into photons by stacking several active regions.

The optimized diode laser chips are then sent to TRUMPF, Laserline and Jenoptik, who will use them to build diode laser stacks (several bars stacked on top of each other) with a high packing density and consequently high irradiance. Highly effective cooling is particularly important to ensure long lifetime and avoid temperature-induced spectral drifts. The diode laser stacks will serve as building blocks for the pump modules, in which the stacks are arranged in two-dimensional arrays. TRUMPF and Laserline are also working on this in the project. In addition, the project partners are investigating the potential to optimize the current drivers, which should provide current pulses of more than 1,000 amperes with as little loss as possible. Beam shaping and beam guidance are also on the agenda. Fraunhofer ILT is developing specially optimized optics suitable for automated assembly to collimate and homogenize the beam profile. In all of this, the partners will have to look at how scalable the modules are to higher outputs and pulse energies as well as at systematic cost control.

Raising the power of diode laser pump modules to a new level

In the joint project, Fraunhofer ILT is primarily addressing modeling and optimization the diode laser bars as well as design of optical systems for beam shaping. Another goal is the automated characterization of the diode laser stacks and pump modules. The Aachen-based research institute is also contributing AI expertise: Among other things, ILT’s engineers are focusing on accelerated micro-optics alignment, online optimization of the pump beam profile and solder-based assembly technology for the micro-optics. In the future, AI will also optimize the automated production of the pump modules and their individual components in order to ensure greater efficiency, faster cycle times and lower production costs at this level as well.

Over the course of the project, Laserline and TRUMPF will each build different pump modules that will pump a high-energy laser in an initial demonstrator. The consortium is aiming to push diode laser-based pump modules into the megawatt range. The objective is highly ambitious. After all, the joint project is scheduled to run for just three years, and the clock is ticking: The German government is aiming to build the first fusion power plants as early as the 2040s. In the funding program “Fusion 2040 – Research on the Way to the Fusion Power Plant,“ the DioHELIOS project, which has now been launched, is driving forward the systematic development of laser-based inertial confinement fusion to a commercially viable technological level. The BMBF is funding DioHELIOS under the funding code (13F1015A - F) with a total of 17.3 million euros at an average funding rate of 66.3 percent.

Wissenschaftlicher Ansprechpartner:

Dr. rer. Nat. Martin Adams

Group Optics Design and Diode Lasers

Telephone +49 241 8906-509

martin.adams@ilt.fraunhofer.de

Dipl.-Ing. Hans-Dieter Hoffmann

Head of Department Laser and Optical Systems

Telephone +49 241 8906-206

hansdieter.hoffmann@ilt.fraunhofer.de

Dr.-Ing. Martin Traub

Group leader Optics Design and Diode Lasers

Telephone +49 241 8906-121

martin.traub@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen, Germany

www.ilt.fraunhofer.de

Weitere Informationen:

https://www.ilt.fraunhofer.de/en.html

Ähnliche Pressemitteilungen im idw