New Method for new Materials

Physicists at the University of Magdeburg develop low-cost production process for transition metal nitrides in high industrial demand

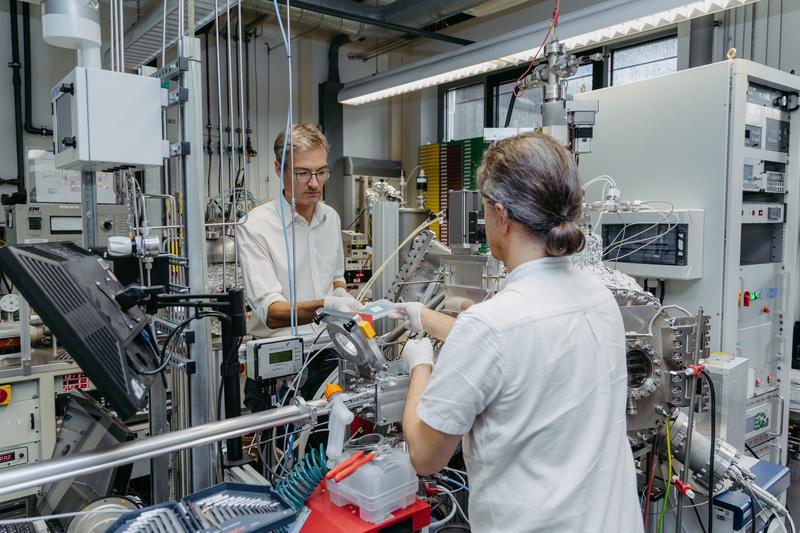

A team of researchers at Otto von Guericke University Magdeburg has developed a new process for producing transition metal nitrides cheaply and more energy-efficiently. Endowed with additional and application-related functionalities, these innovative materials could in future play, among other things, a key role in electronics and communication technology and, for example, significantly improve data transmission in mobile phone networks.

As part of a research project received funding of 2.8 million euros by the European Fund for Regional Development (ERDF), the physicists aim to use what is known as the sputter epitaxy technique for the first time to produce these chemical compounds efficiently and to suit specific applications as well as to optimize the properties of the transition metal nitrides in such a way that entirely new technological fields of application will be possible as a result.

Professor Martin Feneberg, who, together with his colleague, Professor Armin Dadgar, is leading the research project, explains that transition metal nitrides play a key role in material science. “Transition metal nitride compounds from elements such as titanium or vanadium boast extraordinary physical demonstrate,” he says. “They are especially durable, heat resistant and chemically stable - properties that make them extremely attractive for countless industrial applications.”

Professor Dadgar goes on to explain that these material properties open up new technological potential, especially in electronics, where transition metal nitrides can be used as coatings for high-performance transistors or as conductive materials for fast, efficient data transmission. “In mobile phone technology and optoelectronics in particular, these materials are highly promising. In order to satisfy the increasing requirements for 5G data transmission speeds, radio cells must become smaller and more powerful. Transition metal nitrides could play a central part in this.”

The sputter epitaxy technique makes it possible to produce thin layers of transition metal nitrides at lower temperatures and for considerably less cost. “With this process, a gas, usually argon, is placed in a chamber under an electric current and forms plasma,” explains Professor Dadgar. “The energy-rich particles in the plasma meet a so-called target material and release atoms, which then are deposited in an ordered crystalline structure on a surface. These ordered layers are especially beneficial for electronic applications.”

The Magdeburg researchers are concentrating on titanium and yttrium compounds, which are of great interest for use in high-performance transistors and energy-efficient devices. “Here at the University of Magdeburg we are setting an innovative tone in materials research with this method, which we now hope to develop further with the support of the EU,” explains Professor Feneberg.

An important part of the project is to educate young scientists. Master’s and doctoral theses worked on as part of the project should contribute towards consolidating the findings obtained and applying them in practice. “In the long term, we hope not only to drive research in Magdeburg forward, but also to strengthen the innovative capability and technological expertise in the entire region,” stresses Professor Feneberg.

The research project will be funded by the European Fund for Regional Development (ERDF) until the end of 2027 under the title “Development of new transition metal group III nitride semi-conductor layers for microelectronics” under reference number ZS/2023/12/182333. More information on http://www.uebergangsmetallnitride.ovgu.de

Wissenschaftlicher Ansprechpartner:

Prof. Martin Feneberg

University of Magdeburg

Institute of Physics

Telephone: 0391 67-58902

Email: martin.feneberg@ovgu.de

Weitere Informationen:

http://www.uebergangsmetallnitride.ovgu.de Website of the project

Ähnliche Pressemitteilungen im idw