Fraunhofer IZFP research team receives the Joseph von Fraunhofer Prize 2025

Aluminum Production — Ultrasound Reliably Detects Inclusions: Thanks to its physical properties, aluminum plays a major role in the circular economy and achieving climate neutrality. High material quality is crucial during processing, as any contamination present in the aluminum during smelting diminishes the quality of finished components. Unlike existing methods of analysis, the ultrasound-based AloX measuring system from the Fraunhofer Institute for Nondestructive Testing IZFP can detect existing inclusions not only reliably but also quickly and at low cost. The team of researchers was presented with the Joseph von Fraunhofer Prize for 2025 for developing this innovative tool.

Large, hard-to-access equipment and high temperatures: Foundries are home to extreme conditions. Working with liquid metal requires flexibility and resilience in humans and machines alike. With an eye to this challenging environment, a team of researchers from Fraunhofer IZFP was tasked with developing a new measuring system for customers from the aluminum industry to detect contamination in molten metal — an important tool during the production process.

Contaminants as safety risk

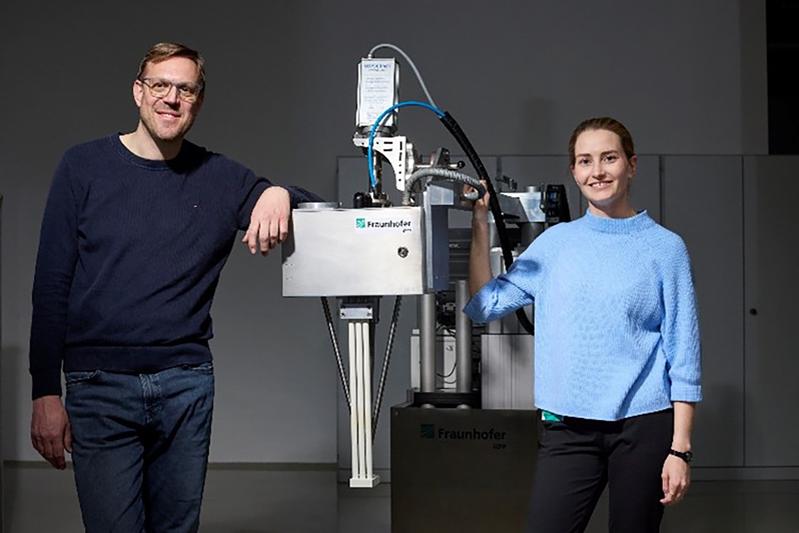

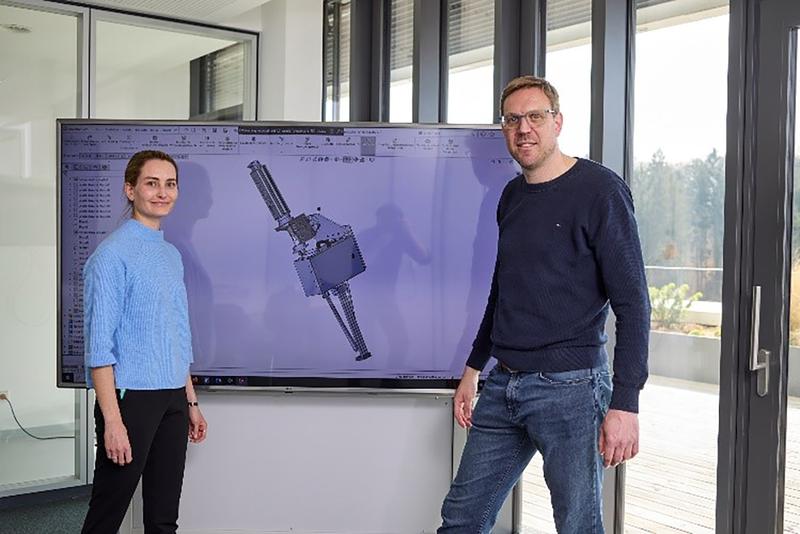

“The purity of the molten metal, whose temperature ranges from 600 to 800 degrees Celsius, is hugely important to the final product later on. For example, any ceramic particles that may be present in the melt don’t liquefy until they get to a temperature of 2,000 degrees or more, and they remain in the finished component as inclusions if they aren’t deliberately removed. This can lead to cracks and holes, and thus in the worst case to component failure,” says Thomas Waschkies, Chief Scientist for Sensor Physics at Fraunhofer IZFP. From the start, he headed the project jointly with his colleague Andrea Mross, who now works in the area of strategy and research programming at the institute in Saarbrücken.

Aluminum: key to the circular economy and climate neutrality

After steel, aluminum is the most widely used metal worldwide. It plays a major role in climate neutrality due to factors including its use in lightweight construction. It also requires little energy input to recycle, so it is a pivotal element of the circular economy. Various measurement systems are already available on the market for quality control when working with molten aluminum, but they are expensive, can only be operated by specially trained experts or are highly time-consuming to use, and thus only spot checks are possible. This means the industry needs a low-cost system that can be operated without special knowledge, delivers final results quickly and can be used flexibly in foundry settings.

Ultrasound-based measuring system for aluminum production

This was the background for the idea, born at Fraunhofer IZFP, of a mobile, ultrasound-based measurement system for molten aluminum. The AloX project was launched, with a name derived from “aluminum melt” and “oxide inclusions.” How the system works can be described using an everyday analogy. “It’s a lot like a parking sensor in a car in that the system, immersed in the molten metal, transmits signals that then bounce off a reflector. If any particles — meaning contaminants — float by, there is a disruptive signal,” Mross explains. Those signals make it possible to take action right there on the production floor to assure quality.

The challenge in developing the system lay first and foremost in the extreme conditions prevalent in the foundries where it is intended for use. The hot molten metal radiates a great deal of heat, affecting not only the system itself but also the entire load-bearing unit. Molten aluminum is also highly corrosive to metal materials. Working closely with industry, the team ultimately developed an initial prototype. The measuring trolley features a measuring unit equipped with special ultrasonic waveguides and built-in cooling, along with a specially developed software program with a patented analysis algorithm. The change mechanism for the ultrasonic waveguides made from titanium is also patented at this point.

Further development for industrial use

The team is currently working on AloX 2.0, which has been further optimized compared to the first version. But one factor has remained the same: Almost all of the components were developed in-house at Fraunhofer IZFP. “From the ultrasonic sensors to the analysis software, electronics and the mechanics of the housing, AloX is an all-in-one package from a single source,” Mross says. The next step for the researchers will be moving the system into broad industrial application, initially in aluminum production. But other potential uses are also conceivable, such as for quality control of other types of molten metal or in production of adhesives and foods.

Wissenschaftlicher Ansprechpartner:

Dr. Thomas Waschkies

Fraunhofer-Institut für Zerstörungsfreie Prüfverfahren IZFP

Sensortechnologien Akustik / Ultraschall | Chief Scientist

Campus E3 1 | 66123 Saarbrücken |

thomas.waschkies@izfp.fraunhofer.de

Andrea Mroß, M.Sc.

Fraunhofer-Institut für Zerstörungsfreie Prüfverfahren IZFP

Strategie & Forschungsprogrammatik / Innovationsmanagement

Campus E3 1 | 66123 Saarbrücken |

andrea.mross@izfp.fraunhofer.de

Weitere Informationen:

https://www.izfp.fraunhofer.de/en/Presse/Pressemitteilungen.html

Ähnliche Pressemitteilungen im idw