Satellite-based laser communication ready for series production

Laser communication promises data rates in the gigabit to terabit range - significantly higher than conventional wireless connections. Europe wants to expand its expertise in this field and install its own satellite networks in the future. Together with the companies TESAT and SPACEOPTIX, researchers at the Fraunhofer Institute for Applied Optics and Precision Engineering IOF have now developed a transmitting and receiving telescope for satellite-based laser communication, which could form the basis for such a network as a series product.

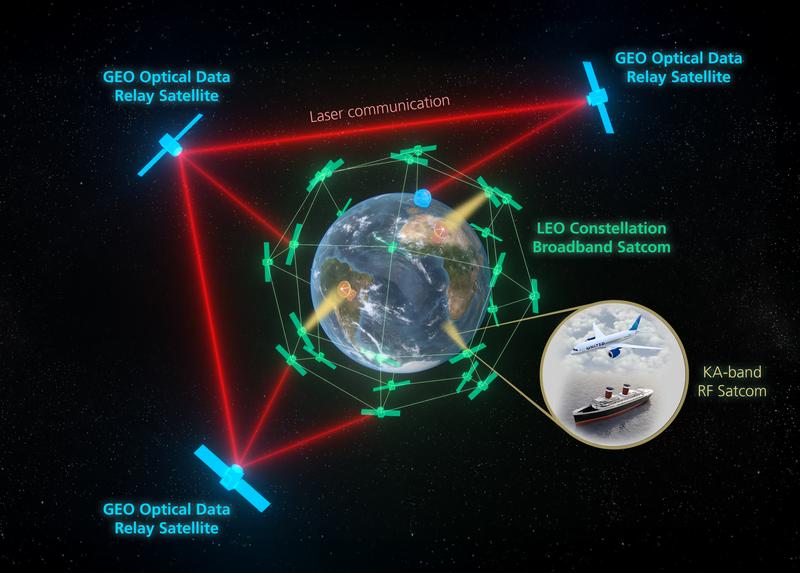

Fast and secure data exchange - even in remote areas: that is the promise of laser communication. With his Starlink network, tech mogul Elon Musk has been working for several years to install a network for nationwide satellite communication in low earth orbit. Europe is also aiming for these spheres and at the same time wants to make itself independent of providers and suppliers from abroad in the field of laser communication. Technological sovereignty is the goal, especially in critical infrastructures such as security and civil protection.

The European Space Agency (ESA) is therefore supporting European research institutions and companies in researching and developing their own systems and expertise with its ScyLight ("Secure and Laser communication technology") program. One of these companies implementing a development project to provide technology as part of the ScyLight program is TESAT, a company based in Baden-Württemberg (Germany) with a long tradition in satellite communication and which has also been building laser communication systems for many years, including the SCOT135 system, a scalable optical communication terminal specially developed for use in medium earth orbit (MEO) and geostationary earth orbit (GEO).

"Every hour of production time counts"

Researchers from Jena have spent three years developing a space-robust transmitting and receiving telescope for this laser terminal, which - unlike science-oriented telescopes, for example - can be manufactured not only in small quantities but also in series. "Our aim was to develop a robust and cost-effective series product," explains Dr. Henrik von Lukowicz, the responsible project manager and head of the Optical and Mechanical System Design department at Fraunhofer IOF. "For systems that are to be manufactured in large quantities, every hour of production time is ultimately important."

The SCOT135 system is expected to achieve a bandwidth of up to 100 Gbit/s and bridge distances of up to 80,000 km with the help of the telescope developed in Jena. "This is new in combination with terminals, which are built in large numbers and will eventually be linked to form an inter-satellite network," says von Lukowicz. "We have developed a universally applicable telescope that is both a transmitter and receiver unit."

Robust design for demanding conditions

When used in space, the telescope must withstand both the environmental stresses encountered there and the stresses caused by the operation of the system itself: "Relatively high laser powers are used in laser communication systems. Up to 50 watts are used here. For a space telescope, this is a relatively high amount of power that propagates through the system," explains von Lukowicz. "This leads to heat build-up, which can cause changes to the optics. But of course the performance of the system must not be impaired as a result. Thermal management was therefore a particularly important aspect of our design."

In addition to thermal regulation, a wide range of expertise from Fraunhofer IOF was incorporated into the design development, based on years of experience with space projects at the institute. "This involves a wide range of issues, such as how to manufacture particularly lightweight components for space flights, methods for the robust adjustment of components and the finest structuring of the optics for precise performance," explains von Lukowicz. "We have combined many of our skills and capabilities in this telescope."

Design at Fraunhofer IOF, production at SPACEOPTIX

The design of the telescope was developed by researchers at Fraunhofer IOF in Jena. The new space company SPACEOPTIX, a Fraunhofer IOF spin-off, is responsible for production at the Isseroda site in Thuringia (Germany). SPACEOPTIX has already manufactured five systems for TESAT. In future, a further 50 units per year may follow. "The industrial series production of highly complex systems requires new ways of thinking. This is precisely where our strength lies: setting new standards and opening up new markets in New Space," says Dr. Frank Burmeister, former Fraunhofer researcher and now Head of Research and Development at SPACEOPTIX GmbH.

The first flight models were successfully delivered to TESAT in June. "The transmitting and receiving telescope developed in Jena is an important key component for our SCOT135 system. The collaboration with Fraunhofer IOF and SPACEOPTIX has brought us a big step closer to our goal of becoming a central enabler for European laser communication not only for near-Earth laser-based satellite networks but also in medium and geostationary orbits," summarizes Dr. Frank Heine, Chief Developer for Laser Systems at TESAT.

About Fraunhofer IOF

The Fraunhofer Institute for Applied Optics and Precision Engineering IOF in Jena conducts application-oriented research in the field of photonics and develops innovative optical systems for controlling light - from its generation and manipulation to its application. The institute's range of services covers the entire photonic process chain from opto-mechanical and opto-electronic system design to the production of customer-specific solutions and prototypes. At Fraunhofer IOF, about 500 employees work on the annual research volume of 40 million euros.

For more information about Fraunhofer IOF, please visit: www.iof.fraunhofer.de

About TESAT

TESAT is a leading manufacturer of satellite equipment. The product range spans the smallest space-specific components to modules, entire assemblies or payloads for telecommunication, navigation, earth observation and science missions. In Backnang, Germany, more than 1,100 employees develop, assemble and test systems and equipment for satellite communications. TESAT is the technology leader for in-orbit-verified optical communication terminals for data transmission via laser and has a focus on commercial and institutional space programs. As the leading manufacturer in its field, the company helps to sustainably connect the world and make it a better place to live for everyone.

Learn more about TESAT at www.tesat.de

About SPACEOPTIX

SPACEOPTIX GmbH is a medium-sized company specializing in the development and manufacture of metal-optical mirrors and mirror systems for applications in space, semiconductor technology and industry. Founded as a spin-off of the Fraunhofer IOF in Jena, with decades of experience in applied science, SPACEOPTIX today develops and manufactures high-performance optical components and systems from prototype to series production at its production site in Thuringia. The main applications are in the development, production, assembly and testing of sophisticated optics for earth observation and optical laser communication.

Further information about SPACEOPTIX GmbH can be found at: www.spaceoptix.de

Wissenschaftlicher Ansprechpartner:

Dr. Henrik von Lukowicz

Fraunhofer IOF

Head of Department Optical and Mechanical System Design

Phone: +49 3641 807- 396

Mail: Henrik.von.Lukowicz@iof.fraunhofer.de

Ähnliche Pressemitteilungen im idw