As Unique as Every Hand: Exoskeletons Helping Patients of All Ages and Genders Regain Independence

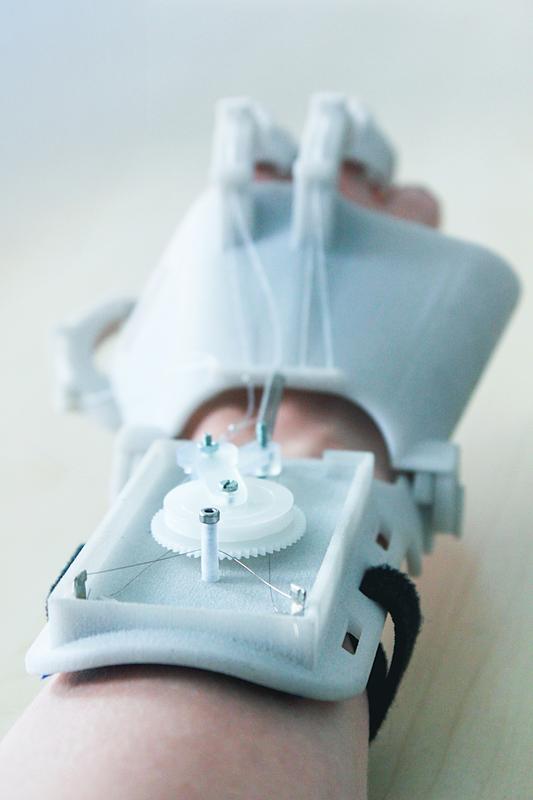

Hand mobility is often impaired after tendon injuries or as a result of strokes. In therapy, exoskeletons increasingly serve to support recovery. These devices fit over the hand like a second skeleton and can assist with controlled movements of the wrist and fingers. However, only products specifically tailored to an individual hand—and meeting key requirements such as low weight and compact design—offer a real chance of therapeutic success. After all, a support and motion aid that hinders more than it helps will likely end up collecting dust on a shelf.

The Foundation: CAD Modeling and Innovative 3D Printing

The Fraunhofer Institute for Machine Tools and Forming Technology (IWU) utilizes innovative shape memory alloys, stepper motors, and 3D printing technologies to create precisely fitted, gently supportive hand exoskeletons. The idea is that the exoskeleton must first fit perfectly to the anatomy of the hand. Human hands vary not only in size but also in proportion—even the left and right hands of the same person can differ significantly.

The selective laser sintering (SLS) process in 3D printing offers nearly unlimited geometric flexibility. In this process, three-dimensional structures are built up layer by layer from plastic powder. The manufacturing process becomes all the more efficient when based on a parametric CAD model. Ideally, the individual hand is available as a digital 3D scan, allowing for mapping the geometric shape as well as the relationships (parameters) between specific hand elements. This results in an extremely precise "negative" of the hand, and any future adjustments or remakes are easier to implement with the CAD model as a reference.

Compact, Lightweight, and Precise Drive System

But it is not just the anatomy of each hand that is unique—grip strength varies widely too. For most female patients and many children, it is essential to individualize the force and motion range of a hand exoskeleton. At the same time, a heavy device would be particularly burdensome for this group.

Thus, beyond a precise fit, the drive system plays a crucial role. Alina Carabello, a PhD candidate at Fraunhofer IWU and research associate at Chemnitz University of Technology, developed a drive system that combines a bidirectional stepper motor with actuated wires made from shape memory alloys (SMAs). This design uses just two artificial tendons, precisely controlled by the motor to enable both flexion and extension of the hand and fingers. Multiple positions can be held and fine-tuned as needed—for example, when gripping a plastic water bottle that softens after opening due to escaping carbonation.

How the Drive System Works:

The stepper drive includes components like gears, levers, pawls, and SMA wire. When the wire is heated, it contracts, causing the lever to rotate by a defined angle. This rotation moves the gear, winding or unwinding the tendon for flexion or extension. A movement that either bends or straightens the finger. In the system designed by Carabello, the SMA wires act as actuators—their ability to change shape drives the motion of the gear. When heated via electrical current from a microcontroller, the SMA wire contracts. Upon cooling, it elongates again, either by a return spring or another SMA wire. This mechanism powers the artificial joints of the exoskeleton. The result is precise and repeatable motion; the gentle actuation behavior of the SMA wires ensures safe and smooth movements.

Personalized Exoskeletons for Therapeutic Purposes

Fraunhofer IWU recognizes a growing need for individualized assistive devices in medical technology to reflect patient needs and provide more effective support for healthcare professionals. Many assistive devices are based on standardized designs and rarely account for variables like age, gender, size, weight, or specific limitations—and often cannot be adjusted at all.

The hand exoskeleton developed by the Fraunhofer IWU specifically addresses tendon injuries caused by accidents. However, the apparatus is also valuable after strokes or in cases of (congenital) paralysis, where it is essential to mobilize the affected hand during recovery. Often, more frequent exercise sessions would be beneficial—but therapist time is limited. In such cases, the Fraunhofer IWU exoskeleton provides relief, enabling movement support without constant supervision.

Wissenschaftlicher Ansprechpartner:

Dr. Kenny Pagel

Fraunhofer Institute for Machine Tools and Forming Technology IWU

Nöthnitzer Straße 44

D-01187 Dresden

+49 351 4772-2343

Kenny.Pagel@iwu.fraunhofer.de

Originalpublikation:

https://www.iwu.fraunhofer.de/en/press/2025-as-unique-as-every-hand-exoskeletons-helping-patients-of-all-ages-and-genders-regain-independence.html

Ähnliche Pressemitteilungen im idw