Iridium-reduced catalysts for the cost-effective production of green hydrogen

After two years of research and development, the German-Chilean project Power-to-MEDME-R&D was successfully completed. The focus was on sustainable production of green hydrogen as well as the derivatives methanol and dimethyl ether (DME) in Chile. Researchers at Fraunhofer Institute for Applied Polymer Research IAP developed iridium-reduced catalysts for hydrogen electrolysis. These reduce the cost of hydrogen production and are scalable through a unique process – a central foundation for industrial-scale hydrogen production and economic utilization.

New PEM catalysts with lower iridium content

Catalysts are indispensable components for the production of hydrogen in electrolyzers. They accelerate electrochemical reactions, often making them economically viable in the first place. The precious metal iridium is a proven catalyst for water electrolysis. Worldwide, iridium is rare and expensive. Researchers at Fraunhofer IAP have synthesized novel catalysts for proton exchange membrane (PEM) electrolyzers that require significantly less iridium than previously used – without sacrificing performance. “Our newly developed catalysts contain only seven milligrams of iridium on an area of 25 square centimeters, but achieve the performance of layers with four times as much iridium,” explains Dr. Christoph Gimmler, head of the Nanoscale Energy and Structural Materials department in Fraunhofer IAP’s Center for Applied Nanotechnology CAN. Initial tests confirm that the performance standard is achieved even though the iridium content is significantly lower. “With these novel catalysts, we substantially reduce the need for expensive iridium, lower the cost of hydrogen production, and create financially viable solutions for the hydrogen economy,” emphasizes Gimmler. The next step will be to conduct long-term tests. The research team is currently looking for project partners for this.

Nanoparticles as drivers of the energy transition

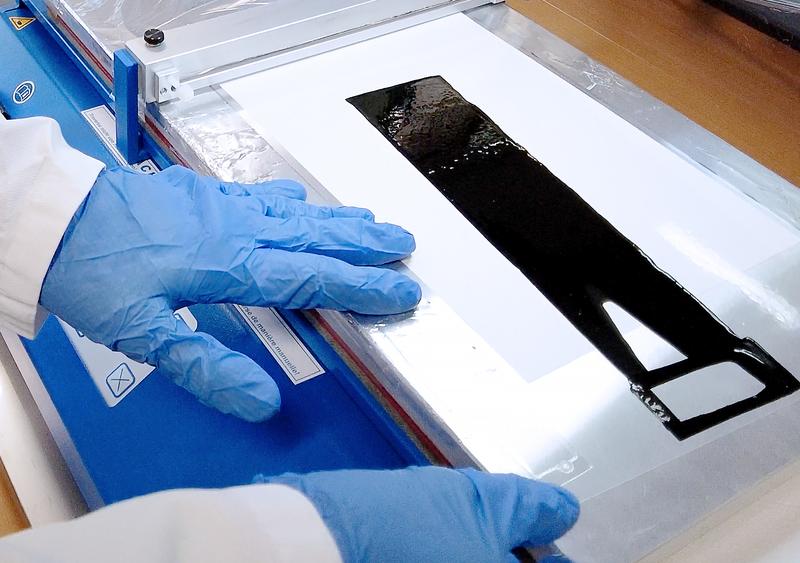

The development of innovative materials for energy applications is an essential part of the research work at Fraunhofer IAP. Efficient and cost-effective catalysts for electrolysis and use in fuel cells are the basis for the production and use of hydrogen and thus for the energy transition. To quickly make the newly developed catalysts economically competitive, the researchers are pursuing scalable synthesis: continuous flow synthesis. The process developed and patented at Fraunhofer IAP enables industrial-scale production of high-quality, precisely defined catalyst nanoparticles – a key prerequisite for the transition from hydrogen and energy research to commercial application, as outlined by the German government’s High-Tech Agenda with the Lab to Fab concept.

About the Power-to-MEDME R&D project

The project, funded by the German Federal Ministry of Research, Technology and Space (BMFTR), ran from October 2023 to 31 December 2025. The aim was to examine the entire value chain of power-to-X products – starting with the production of green hydrogen from renewable energies to the synthesis of methanol and DME – and to evaluate it holistically in technical, economic, ecological, and social terms. The project was managed by Fraunhofer IEE; other participants included Fraunhofer Chile Research, the Fraunhofer Institute for Solar Energy Systems ISE, the Fraunhofer Institute for Microengineering and Microsystems IMM, the Fraunhofer Institute for Silicate Research ISC and its HTL center, the Fraunhofer Institute for Applied Polymer Research IAP, the Fraunhofer Institute for Ceramic Technologies and Systems IKTS, RWTH Aachen University and the RILLL Research Institute on Lifelong Learning, as well as the German-Chilean Chamber of Industry and Commerce AHK Chile.

Weitere Informationen:

https://www.iap.fraunhofer.de/en/press_releases/2026/iridium-reduced-catalysts-cost-effective-production-of-green-hydrogen.html

Ähnliche Pressemitteilungen im idw